Healthcare Supply Chain Management Strategies and Future Trends

The primary goal of healthcare supply chain management is to ensure that doctors and patients can access everything they need to perform all the procedures without any delays. Meanwhile, hospitals must avoid overstocking, track the expiration date, monitor storing conditions, etc.

Below, you will discover the logistics and supply chain management in healthcare, issues, and top technologies that help optimize processes.

Supply chain in healthcare — basics

The supply chain in the healthcare industry is responsible for delivering medical supplies to final recipients on time.

Supply chain management processes involve healthcare providers in:

- Planning and demand forecasting

- Providing the required materials to doctors

- Delivering medications to dispensing units

- Storing medicines and controlling their condition

- Item returning, repairing, or disposing

- Selecting supplies and making orders

- Testing received items, materials, and medicine

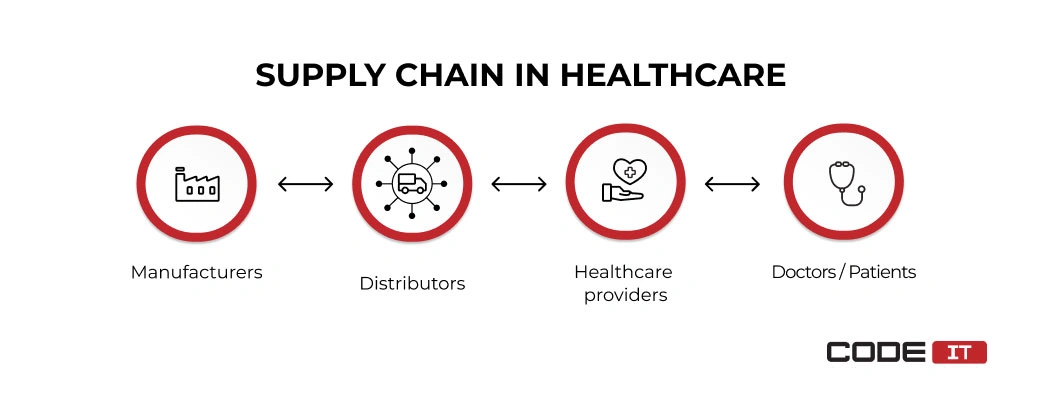

A simple healthcare supply chain implies the following stakeholders.

- Manufacturers — produce materials, equipment, medicine, etc.

- Distributors — source, store, and distribute medical products.

- Hospitals — receive, store, and dispense medication and materials.

- Doctors and patients — request materials and prescribe medicines.

All the stakeholders need to tackle supply chain issues in healthcare to ensure that all parties can access the demanded materials and medicine on time. Also, stakeholders must cooperate effectively to plan, source, store, and distribute medical products.

Custom software — adjusted to your processes

Business First

Code Next

Let’s talk

The key characteristics of a successful supply chain in healthcare are:

- Full visibility. All parties can easily track items’ movement and statuses, in-stock levels, and unforeseen challenges in real time.

- Effective planning. Manufacturers, distributors, and healthcare providers plan the demand for certain medicines and materials, considering seasonal or other regular changes.

- Operative collaboration. All parties exchange medical data to eliminate bottlenecks.

- Fast adaptability. Stakeholders involved in a supply chain can rapidly scale up their processes to rapidly react to predicted changes in demand.

- Efficient storage. Distributors and hospitals maintain storage facilities and maintain the proper storage conditions.

- Quality control. All parties constantly check the quality of received and dispensed items.

Inventory Management in Hospital

Supply chain in healthcare vs other industries

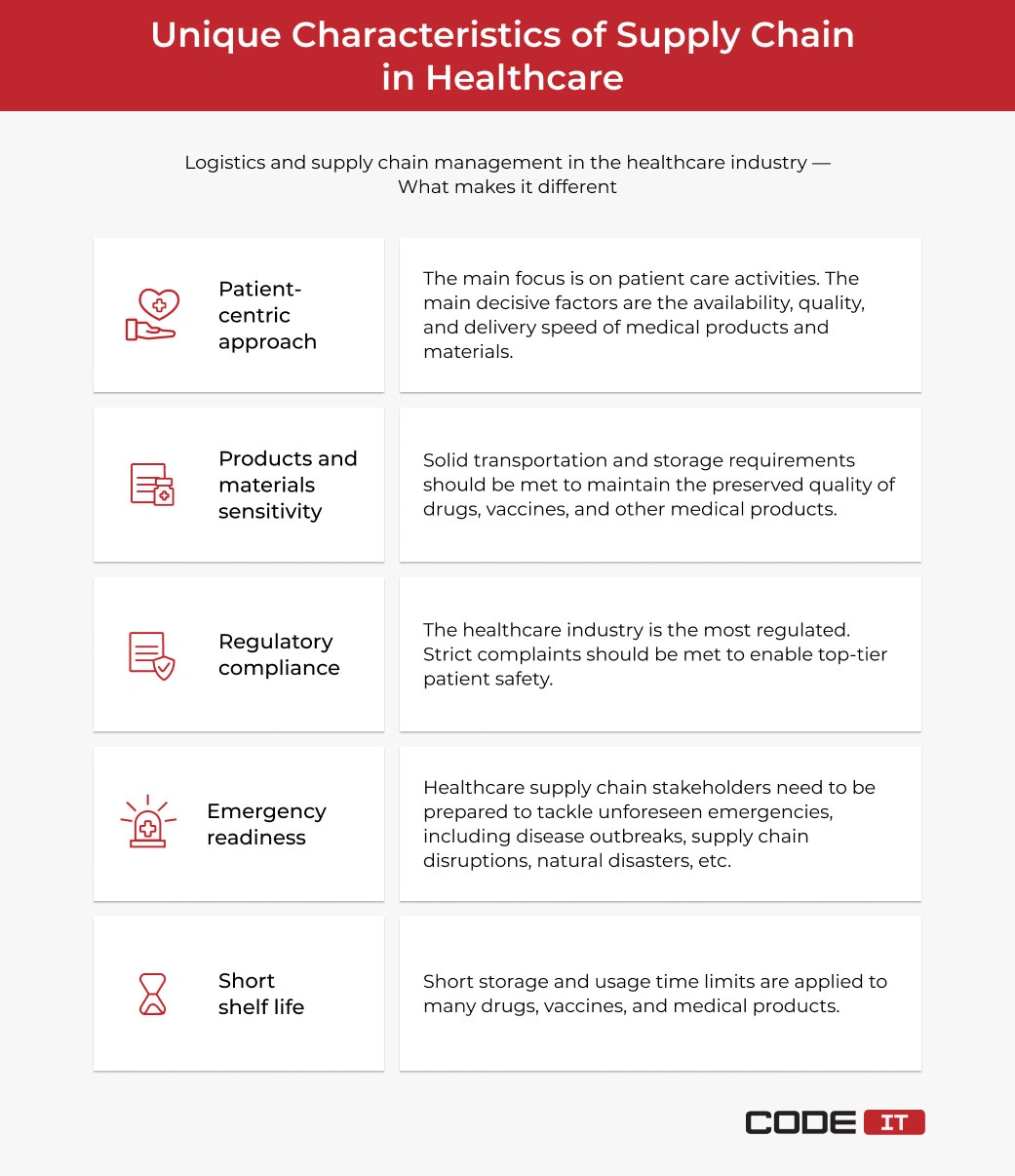

Supply chain management in healthcare is different from many other industries, like consumer goods, automotive parts and materials, food and beverages, electronics, and others. Let’s check what makes it stand out from other industries.

The key characteristics that set supply chain management in the healthcare industry apart from others are as follows.

- Patient-centric approach. All the activities are focused on delivering the right medical products and materials on time to enable top-tier patient care.

- Sensitivity of products. Drugs, vaccines, and other medicines have diverse and solid requirements for storage and transportation environments.

- Regulatory compliance. The healthcare industry has the most significant number of regulatory requirements aimed at enabling patient safety.

- Emergency readiness. Due to the patient-centric approach, medical organizations should be prepared to cope with emergencies, including natural disasters, disrupted supply chains, disease outbreaks, etc.

- Short shelf life. A lot of drugs and vaccines have short storage and usage time limits.

Strategies for effective healthcare supply chain management

Standardization, transparent communication, and comprehensive healthcare inventory control are the core aspects of every successful strategy for the supply chain management.

Below, you will find micro and macro perspectives on the top strategies for effective supply chain management in the healthcare industry.

Macro Perspective

The macro perspective refers to the best supply chain management practices that involve all stakeholders.

Since governments highly regulate the healthcare industry, different countries implement disparate solutions for managing their supply chain. Here are some examples.

| Country | Supply Chain Management Strategy | Outcomes |

|---|---|---|

| Canada | A dedicated product identification system has been developed to enable standardization in a supply chain country-wide. External package labels are put on packages, ampules, vials, etc. The labels enable unification and improve collaboration across the entire supply chain. | Improved patient safety. Optimized supply chain. Enabled medical product traceability. |

| Australia | The digital solution has been developed and used by parties in the Australian health sector, enabling: Data synchronization via the National Product Catalog (NPC) Unified barcoding across the industry Expiry date tracking Electronic messaging between all parties The system helps improve medicine control, individualize patient care, detect fraudulent healthcare operations, etc. | Improved individualized patient care. Over-prescribing reduction. Fraudulent prescriptions identification. 25% decrease in stock receipt creation time. |

| United Kingdom | The Department of Health has released the “Coding for success” guidelines to help stakeholders enable standardization. | Increased patient safety. GS1 coding standard adoption. New supply chain technologies incorporation. |

| Japan | A single product database and unique identification system have been developed to enable the unification of medical products and materials across the healthcare industry. | Adequate stock management. Medical products and materials control. Precise tracking. |

Different strategies have common characteristics—unification, which include the following healthcare supply chain solutions:

- Standardized product identification

- Single electronic product catalogs

- Automatic item identification

- Real-time visibility and product traceability

Micro Perspective

The micro perspective refers to a set of operational healthcare supply chain management activities in a selected hospital or medical organization.

The three core elements of the operational structure in a hospital include:

- Links between nodes

- Information management

- Material flow management

Let’s elaborate on the top three operational elements in more detail.

| Description | Example | Success Factor | |

|---|---|---|---|

| Links Between Nodes | An activity that enables the flow between two different departments/roles is described as a link. | A defined flow of distributing medical products from a storeroom to a warehouse. | Well-defined workflows to define smooth collaboration between all nodes. |

| Information Management | Both integrated and separated information systems in hospitals should enable the opportunity to share patient data securely. | A front office shares patient status, scheduling, lab results, and patient payment info with the back office, keeping the imagination meaning of data. | Standardized data exchange protocols to enable medical data interoperability and exchange data, keeping its unambiguous meaning. |

| Material Flow Management | Medical materials are classified and shared between departments, following defined flows for a specific classification of items. Both departments share responsibility for maintaining the right storage and transportation conditions. | Medical products and materials are delivered from the supply unit to the service unit, maintaining the right transportation conditions. | Centralized healthcare logistics activities control; Categorization of medical items and defined transportation rules. |

Develop innovative supply chain management solutions

Business First

Code Next

Let’s talk

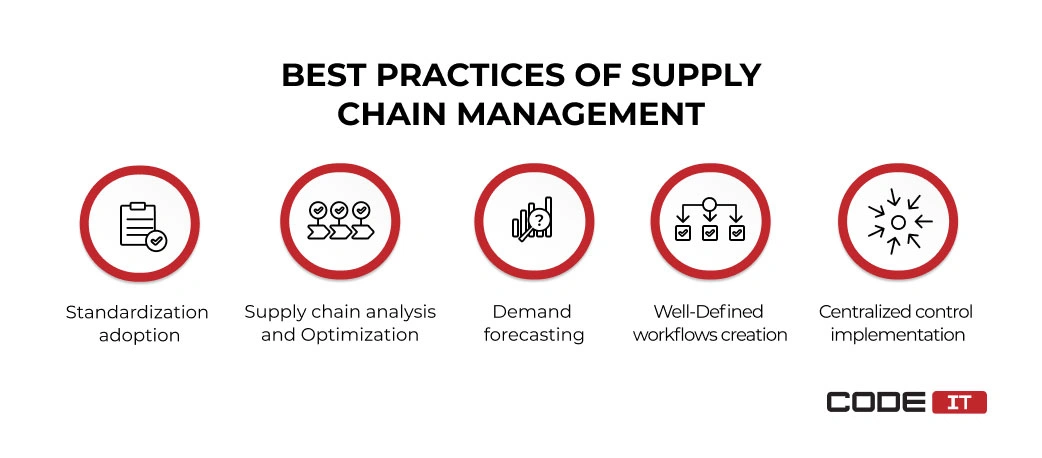

Supply chain management in healthcare — best practices

Stakeholders must create new infrastructure, educate staff, adopt new technologies, etc. The top practices to tackle the majority of supply chain issues in healthcare are listed below.

Standardization Adoption

The standardization approach refers to a set of activities to simply inventory management by using:

- a single database

- unified identification codes

- defined guidelines for all departments

- a list of medical products and equipment to use

| Benefit | Description |

|---|---|

| Streamlined communication | Different stakeholders and departments communicate using standardized messages to avoid using misleading terms. |

| Improved visibility | The usage of single databases and integrated systems enables hospitals to easily trace the movement of medical materials across a supply chain. |

| Enhanced inventory management | Standardized codes help simplify medical product identification and categorization, positively affecting performance. |

| Better product quality | The standardization approach helps identify approved medical materials. |

| Reduced costs | Faster product identification, better traceability, and optimized quality check helps decrease supply chain management expenses. |

Supply Chain Analysis and Optimization

Data should be collected across the entire healthcare supply chain for further analysis. Data can be collected by:

- tracking travel information about medical products and materials

- monitoring and capturing environmental conditions data

- recording data on request placement, order processing time, supplier response

- capturing data related to item delivery delays, turnovers, stockouts

To fetch data from external systems, it’s advisable to enable communication channels with other stakeholders in your supply chain.

| Benefit | Description |

|---|---|

| Enhanced resources usage | The definition of healthcare supply chain activities that can be optimized to source, store, and distribute medical products effectively. |

| Data-baked decision-making | Data analysis helps identify the best logistics and supply chain management strategies in healthcare. |

| Effective problem detection | Supply chain issues in healthcare and disruptions can be rapidly detected by using a data analytics tool. |

Demand Forecasting

There are many strategies for predicting the demand for medical materials and products. In most cases, demand forecasting is enabled through the analysis of historical data.

Mathematical formulas or machine learning (ML) software help predict a lot of changes, including the following:

- future trend changes

- patient demographics

- disease outbreaks

- seasonal changes and patterns

- patient preferences

| Benefit | Description |

|---|---|

| Optimized inventory planning | The analysis of historical data helps stakeholders define patterns and accurately predict changes. |

| Minimized wastage rate | Efficient demand forecasting helps adjust supply chain planning to minimize overstocking, resulting in reduced wastage. |

| Improved patient care | Demand forecasting helps improve the supply chain and prepare better for demand changes, offering patient care without delays and interruptions. |

Well-Defined Workflows Creation

Solid rules and transparent workflows help enable effective collaboration between departments and stakeholders. By following defined instructions, all parties maintain the top quality of products/services and share their responsibility adequately.

| Benefit | Description |

|---|---|

| Improved efficiency | Detailed guides and action flow help all parties effectively perform their healthcare operations. |

| Better collaboration | Transparent workflows and defined roles help departments share responsibility to enable effective collaboration. Also, a list of defined roles helps faster response to emergencies. |

| Reduced errors | Tried-and-tested guidelines followed by all parties help reduce the number of errors and improve the quality of healthcare supply chain management. |

| Faster onboarding | Well-defined instructions and internal policies help rapidly onboard new team members and reduce the time of required mentorship for new employees. |

Centralized Control Implementation

It helps enable effective coordination and monitoring. Usually, it is applied on the operational level, which refers to healthcare providers. Centralized control can be implemented by using integrated systems or pipelines between diverse solutions to submit requests and collect data in one place.

| Benefit | Description |

|---|---|

| Improved coordination | Having centralized control, a healthcare organization can enable smooth and effective collaboration between different departments. |

| Full visibility | A centralized inventory management software can collect, analyze, and provide summarized reports. Also, it can detect changes across a supply chain and notify responsible roles. |

| Better control | Instant access to all the data across a supply chain enables responsible managers to monitor metrics better. Also, they can rapidly respond to negative changes or emergencies. |

Need help in optimizing your supply chain?

Business First

Code Next

Let’s talk

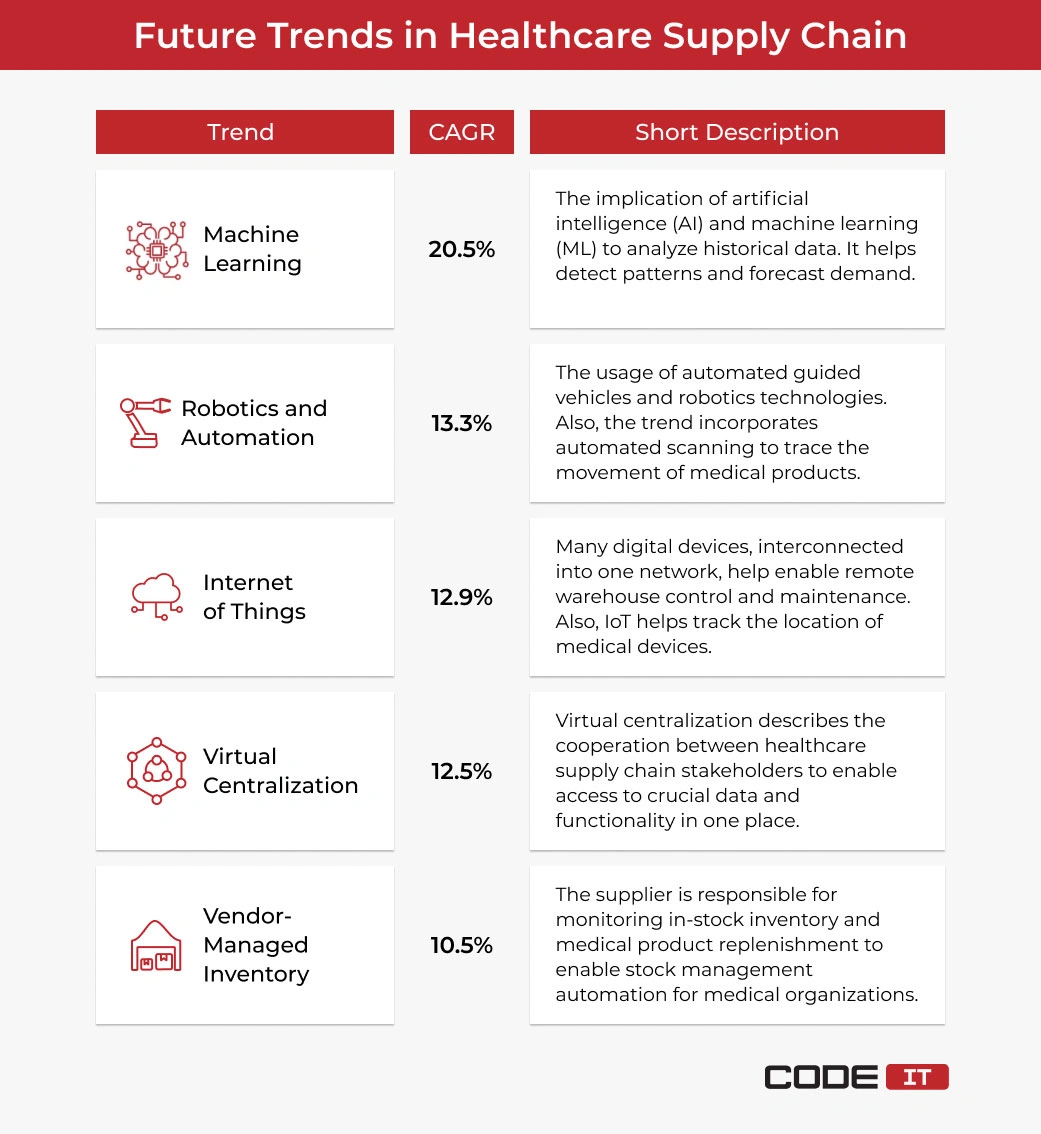

Future trends and innovations in healthcare supply chain

Stakeholders always seek prominent innovations to lower costs. The escalating inflation drives them to opt for new technologies to maintain the prices. The top five future trends and innovations include the following.

Machine Learning — CAGR 20.5%

Stakeholders manage to apply modern technologies to forecast demand changes. Machine learning (ML) is the fastest-growing technology that helps define patterns and predict future demand.

ML-driven data analysis software can outperform mathematical models. The key technology’s advantages lie in the ability of machine learning models in the supply chain to:

- adjust themself by learning from historical data

- define non-linear relationships between variables

- detect complex patterns to predict repetitive events

- analyze data and deliver predictions in live time

Robotics and Automation — CAGR 13.3%

Automated guided vehicles and robotic actuators are the top warehouse automation technologies. They are widely installed in warehouses to automatically move products from storage to packaging and transportation facilities. Also, the trend implies automatic product identification using mechanized barcode scanning, RFID tags, beacons, or other technologies.

Internet of Things — CAGR 12.9%

The Internet of Things (IoT) concept refers to using electronic devices and sensors connected to one network. Stakeholders usually incorporate IoT devices in a supply chain are:

- Inventory management. RFID tags and Bluetooth-enabled devices help track the movement of medical products and materials. Also, IoT devices help rapidly allocate the placement of items.

- Warehouse maintenance. Smart sensors help track environmental conditions like temperature and moisture in warehouses. Also, IoT-enabled systems can automatically adjust HVAC systems to maintain ideal environmental conditions to store medical supplies effectively.

- Patient monitoring. Remote sensors and wearable devices help monitor the condition of patients in real time. All the data collected can be analyzed. Also, IoT devices can alert medical staff about severe health changes.

Virtual Centralization — CAGR 12.5%

The implementation of integrated systems helps enable complete visibility through a healthcare supply chain. Software that drives virtual centralization helps enable the cooperation between stakeholders to access crucial data in one place.

Vendor-Managed Inventory — CAGR 10.5%

The concept of vendor management inventory indicates the approach of shitting the product replenishment responsibility from healthcare organizations to suppliers. Healthcare supply chain companies responsible for distribution need to control the in-stock levels of medical products and automatically create and fulfill replenishment requests.

Healthcare Technological Trends

Supply chain issues in healthcare

The 3 most common healthcare supply chain management challenges are:

- Inconsistent demand

- Lack of visibility

- Quality control

Let’s elaborate on these supply chain issues in healthcare in more detail.

| Description | Statistics | Risks | |

|---|---|---|---|

| Inconsistent Demand | Seasonal variations and unpredicted emergencies cause inconsistent demand for specific materials and medicine. | More than 90% of healthcare providers reported that the Covid-19 outbreak has disrupted their supply chains. | Stockouts and materials/medicine scarcity. Overstocking and increased wastage rates. Higher costs are caused by increased demand. |

| Lack of Visibility | Due to the limited collaboration, all parties can hardly track the movement of items. It makes the process of planning more challenging. | 67% of healthcare providers indicate they lack visibility in their supply chains. | Supply disruptions. Insufficient planning. Quality and compliance issues. |

| Quality Control | Medical providers experience challenges in checking the quality of received materials and medications. | Up to 10% of medications don’t match the regulatory requirements. | Medical materials and medicine returns. Treatment delays. Lawsuits and regulatory fines. |

The other issues that negatively affect healthcare logistics in healthcare are the following:

- Insufficient demand forecasting

- Cold chain management

- Technology adoption

- Supplier reliance

- Regulatory compliance

Let’s take a closer look at the challenges and risks.

| Description | Statistics | Risks | |

|---|---|---|---|

| Insufficient demand forecasting | Stakeholders experience challenges in predicting demand changes due to a large number of factors to consider. | An average medical organization holds up to 13% of excess inventory due to insufficient planning. | Increased stock management costs. Overstocking. Shortage of medical materials. |

| Cold chain management | The maintenance of medical products that require specific conditions, like temperature, humidity, etc. | Roughly 1 out of 4 COVID-19 vaccines were stored or transported in environments that didn’t match requirements during the virus outbreak because of insufficient infrastructure. | Compromised quality of medical products. Expanded wastage rates. |

| New technology adoption | The implementation of new technologies to enable real-time visibility, analytics, automation, etc. | One of three healthcare providers states that digital transformation is the top priority. | Risk of data breaches. Shortage of niche experts to implement new technologies. |

| Supplier reliance | Healthcare providers are highly dependent on several major suppliers who deliver the majority of medical materials and drugs. | More than half of healthcare providers are concerned about their supplier dependency. | Unforeseen supply disruptions. Shortages of crucial materials. Lack of alternative supply sources. |

| Regulatory compliance | All parties have to follow all regulatory requirements strictly. | Healthcare providers may spend up to a ⅕ part of their budgets on compliance-related activities. | Lawsuits and legal penalties. Below-standard patient care. |

Improve your supply chain with CodeIT

Business First

Code Next

Let’s talk

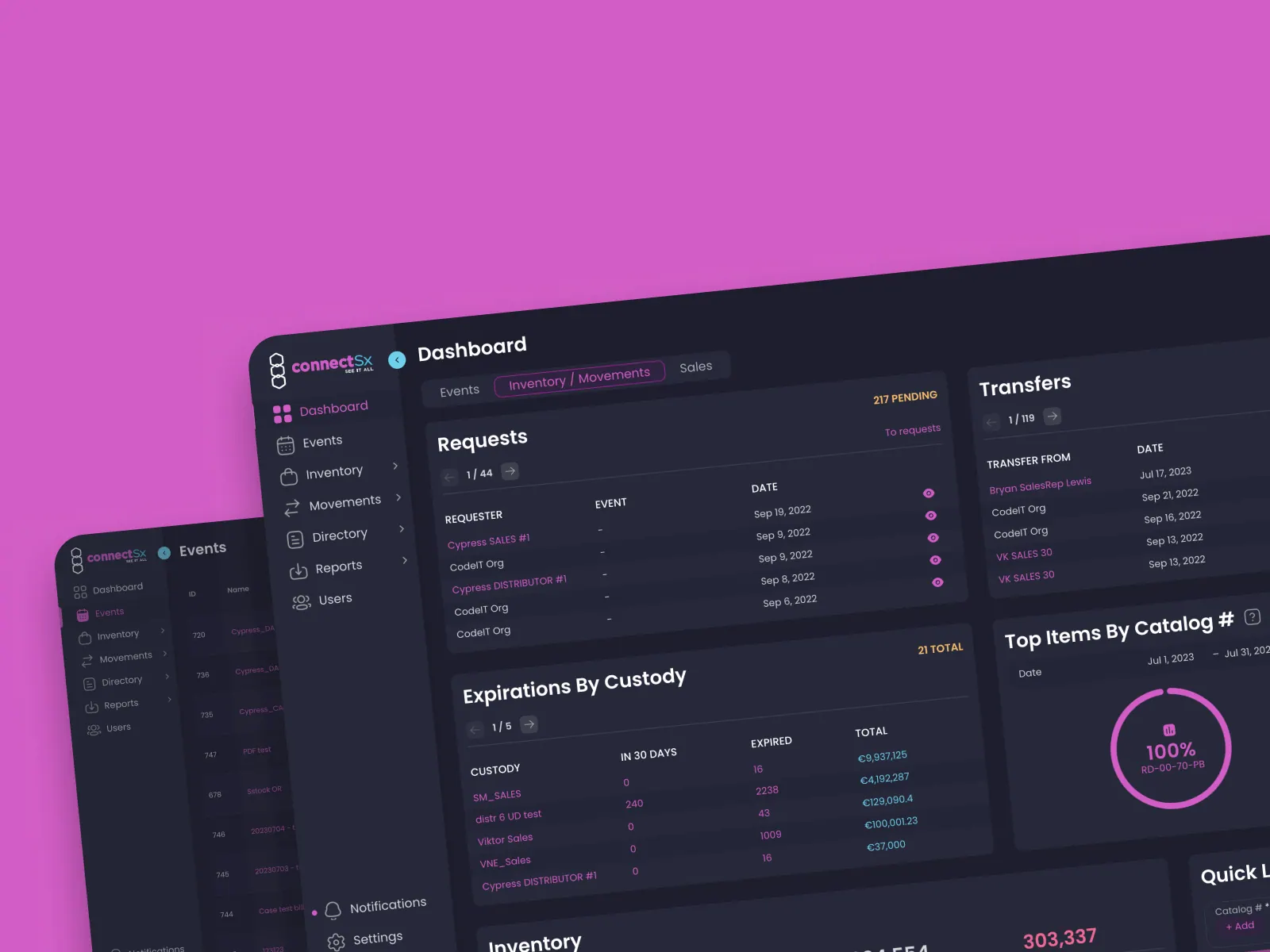

ConnectSx — our expertise

CodeIT has extensive expertise in developing digital solutions. ConnectSx is one of the top systems our team has developed from scratch.

Our team has developed a comprehensive digital solution that helps facilitate healthcare inventory management. The applications we’ve developed comprise the following:

- Inventory management web application

- Inventory management mobile application

- Barcode scanning mobile application

The core functionality of the developed applications includes the following.

- Inventory management. Users can trace medical devices and discover their location. They can easily submit transfer requests, allocate lost inventory, quickly find the required items, etc.

- Third-party integrations. External solutions can easily integrate Information about in-stock inventory into the system.

- Expiration date tracking. The system helps track the expiration date of medical products to decrease the wastage rates. The software automatically notifies responsible roles about expired products.

- Data collection and analysis. The developed applications automatically collect healthcare inventory data, analyze it, and provide summarized reports.

To recap

A healthcare supply chain is a set of activities stakeholders conduct to provide medical providers and patients with the demanded supplies without any delays.

Supply chain management requires effective collaboration between manufacturers, distributors, and medical organizations. All parties need to tackle a lot of challenges, including:

- inconsistent demand and seasonal changes

- unforeseen disease outbreaks

- regulatory compliance requirements

- price maintenance

- storage and transportation requirements for medical products

- product quality testing

To effectively tackle all the challenges, stakeholders apply the best practices, which include the following:

- Standardization — the integration of single databases, unified identification codes, and medical data interoperability.

- Analysis and optimization — data collection and analysis across a healthcare supply chain to define bottlenecks and optimize processes.

- Demand forecasting — the usage of mathematical formulas or machine learning models to analyze historical data and define patterns to predict future demand changes.

- Well-defined workflows — thorough instructions help enable effective collaboration by sharing responsibilities. Also, they help improve performance and onboard new team members faster.

- Centralized control — the implementation of integrated systems to enable centralized monitoring and supply chain management in the healthcare industry.

Hire CodeIT to create advanced solutions

Business First

Code Next

Let’s talk

FAQ

Supply chain management in healthcare defines the cooperation between manufacturers, distributors, medical organizations, and patients to provide access to all the requested products on time. Besides, all parties must comply with storage, transportation, and regulatory requirements when managing supply chain activities.

The best strategies across the healthcare supply chain include:

- Standardized product identification numbers

- Single electronic product catalogs

- Automatic item identification

- Real-time visibility and product traceability

The top operational-level strategies that are usually implemented in hospitals include:

- Strong bonds between nodes

- Information management

- Material flow management

The best strategies across the healthcare supply chain include:

- Standardized product identification numbers

- Single electronic product catalogs

- Automatic item identification

- Real-time visibility and product traceability

The top operational-level strategies that are usually implemented in hospitals include:

- Strong bonds between nodes

- Information management

- Material flow management

The foremost practices applied by stakeholders in a healthcare supply chain are:

- Standardization adoption

- Supply chain data collection and analysis

- Demand forecasting

- Creation of well-defined workflows

- Implementation of centralized control

The top technologies adopted by stakeholders in supply chain management in healthcare (manufacturers, distributors, and medical organizations) include the following:

- Machine learning

- Robotics and automation

- Internet of Things (IoT)

- Virtual centralization

- Vendor-managed inventory

New technologies help healthcare organizations improve efficiency, reduce errors, and cut operational costs. Let’s check how the top technologies are applied in the healthcare supply chain.

- Machine learning — to detect repeating patterns to predict future demand changes.

- Robotics and automation — to optimize healthcare transportation and warehousing.

- Internet of Things (IoT) — to monitor patient health and trace medical equipment remotely.

- Virtual centralization — to monitor all the processes and manage healthcare operations in one place.

- Vendor-managed inventory — to shift the responsibility of tracking inventory and submitting replenishment requests to suppliers.

Build your ideal

software today