Manufacturing Software Development

Surpass boundaries set by machine vendors, revolutionize processes, and incorporate new technologies.

Business First

Code Next

Let’s talk

- Processes automation

- Machine control and maintenance

- Real-time monitoring

- Report generation and analytics

- Inventory management

Custom manufacturing software services

Bridge gaps in your processes and solve problems with pinpoint accuracy by opting for custom software development services.

Collect and analyze large datasets. Extract insights, forecast changes, and explore the root causes of manufacturing issues.

Opt for manufacturing software development to integrate ERP and other third-party systems.

Enable full fusibility of all the inventory processes from raw materials sourcing to finished product distribution.

- Data collection and analysis

- Inventory visibility

- Report generation

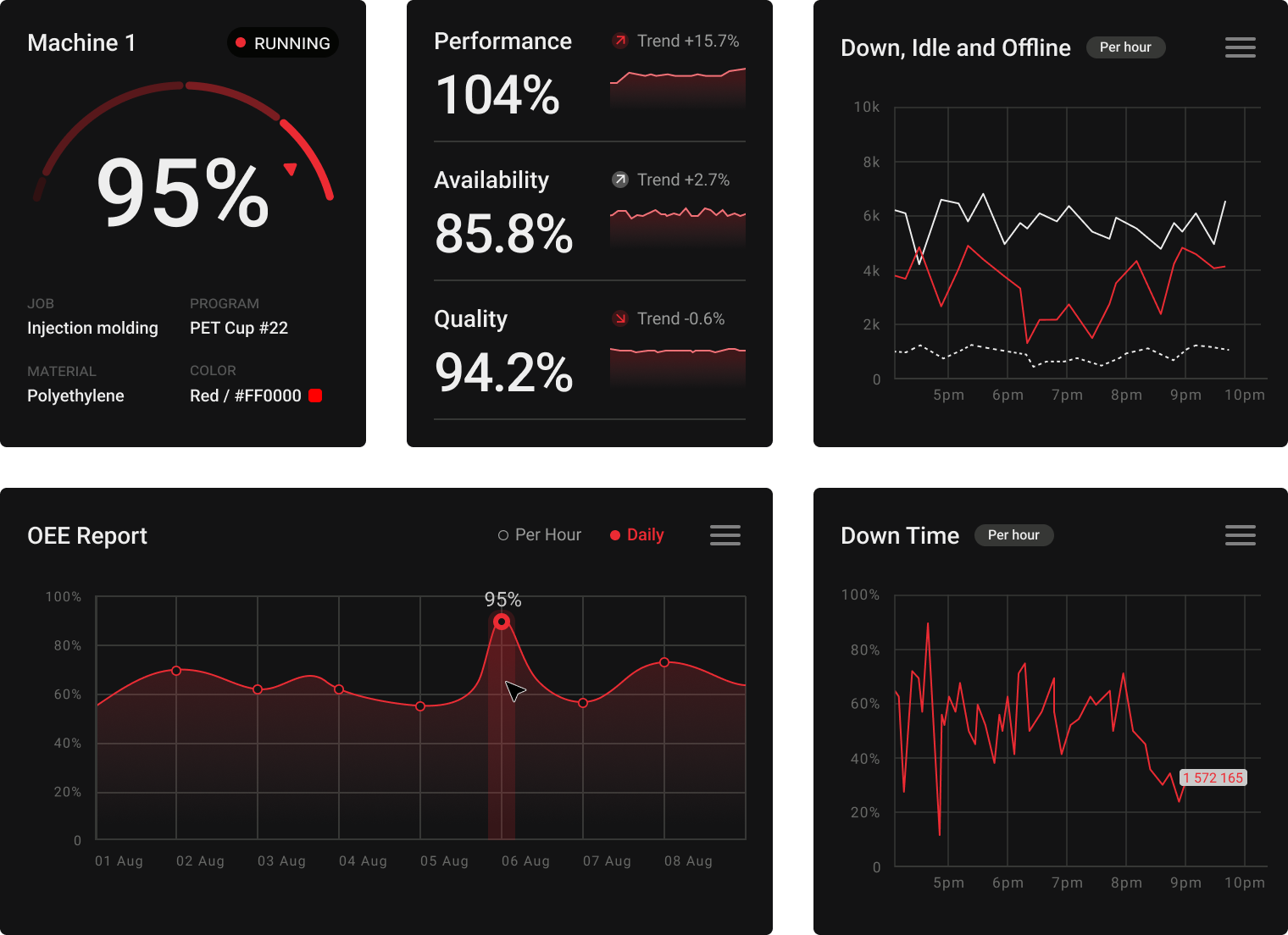

Analyze real-time data collected from product line machines to check their performance.

- KPI and machine status monitoring

- Data visualization

- Historical data collection and analysis

Use a centralized solution to control and monitor all the product line processes.

- Real-time data update

- Dashboards and data visualization

- Historical data storage and summarization

Stay informed about unforeseen issues and anomalies detected in a product line.

- Alerts and notifications

- Anomaly and bottleneck detection

- Product quality control

Automatically detect software malfunction and possible security breaches.

- Continuous software analysis

- Root cause analysis

- Data check and validation

Build a centralized system for collecting and controlling data from smart devices.

- Real-time data collection

- Centralized machines control

- Remote warehouse maintenance

Prevent machine breakdowns and reduce downtime by enabling planned maintenance.

- Downtime prediction

- Automatic parts replenishment

- Machine maintenance planning

Use AI and ML algorithms to define repetitive patterns and forecast demand changes.

- Historical data analysis

- Data validation and normalization

- Forecasting model creation and training

Get insights on energy consumption, define energy usage patterns, and identify idling machines.

- Energy usage reports

- Benchmarking

- Cost analysis

Analyze the information collected from product line machines and develop data-baked insights.

- Data collection and storage

- Report creation & data visualization

- AI-driven data analysis

Collect unstructured data from various sources to learn more about customers.

- Demographics

- Preferences and purchase patterns

- Up-selling opportunities

Identify bottlenecks, inefficiencies, and opportunities for improvement to maintain high productivity.

- Performance dashboard

- Bottleneck identification

- Capacity utilization reports

Create a centralized system for seamless management of all the manufacturing processes. Synchronize workflows and data sources according to your specific business needs.

- Resource usage optimization

- Reduced errors

- Data-backed decisions

Enable complete inventory visibility across all the processes. Track the consumption of raw materials, work-in-progress items, and finished goods.

- Real-time inventory visibility

- Improved order accuracy

- Accurate planning and demand forecasting

Improve customer service, collect feedback, and reduce customer request processing time. Fulfill custom orders considering unique requests from clients.

- Improved customer service

- Faster order processing

- Increased sales

Streamline workforce management by enabling smart scheduling. Run workforce skills assessment and plan upskilling.

- Employee self-service

- Workforce skills management

- Labor force analytics

Collect product line machine data and automate processes. Create an efficient and transparent manufacturing environment.

- Processes automation

- Increased scalability and flexibility

- Fast product line problem identification

Create a single system for managing all the product development stages. Enable seamless information flow and maintain data consistency at all stages.

- Data transformation and validation

- Change tracking

- Accelerated time-to-market

Optimize product inspection processes. Ensure regulation requirements are met and receive reports generated automatically.

- Efficient product quality inspection

- Regulatory requirements compliance check

- Report generation and management

Perfectly align manufacturing processes with the demand and material sourcing capabilities.

- End-to-end visibility

- Supplier collaboration

- Demand forecasting

Industry leaders—powered by our expertise

At CodeIT, we’re all about creating one-of-a-kind manufacturing software. Check out some of the successful projects.

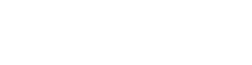

Machine uptime monitoring software

The software helps monitor the operational equipment efficiency.

- Dashboard with product line machine data

- Automatic data analysis and chart creation

- Custom report generation

- Machine status viewer

- System permission configuration

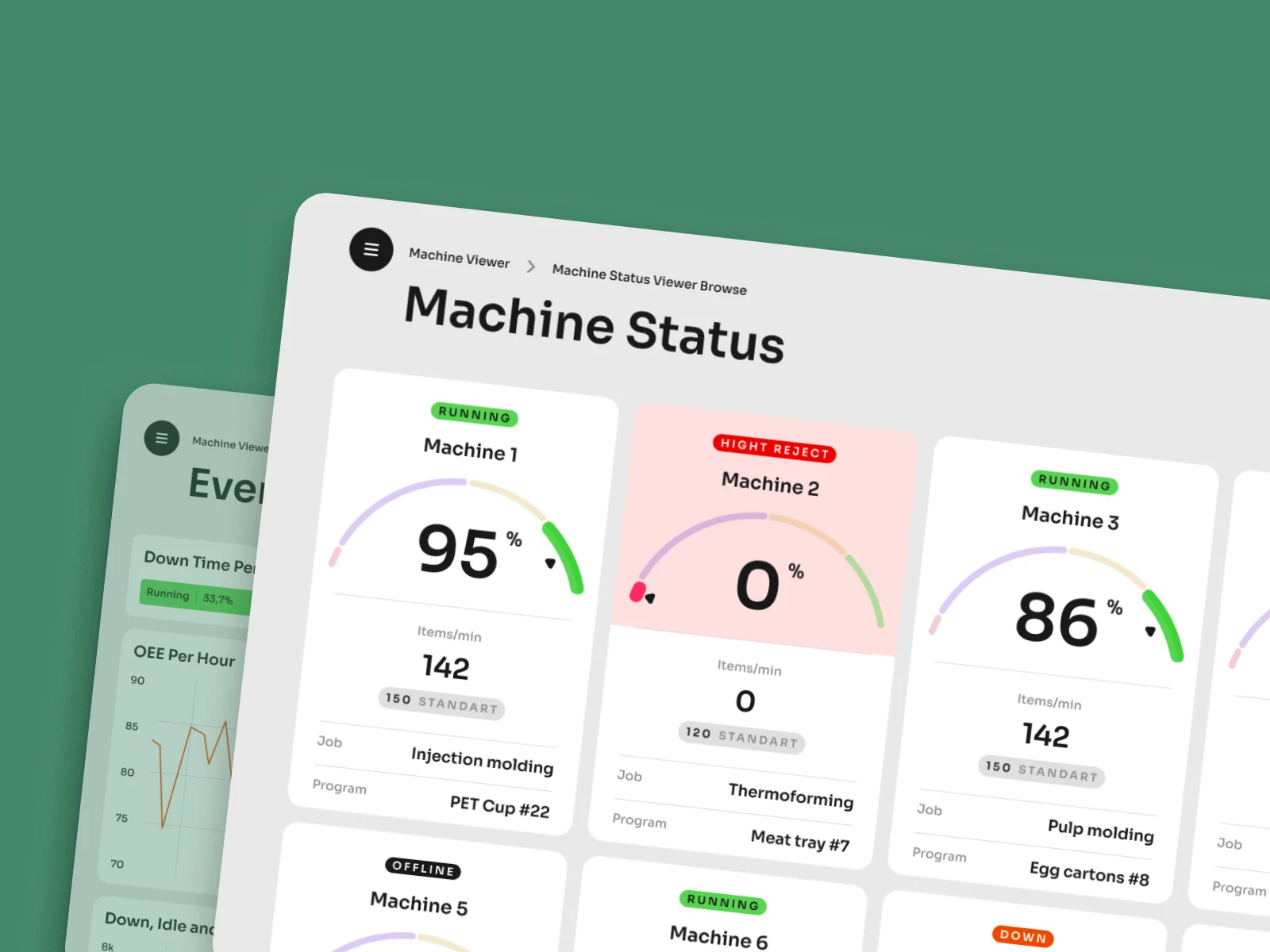

Graphical user interface (GUI) software

The application helps operate an industrial computed tomography machine.

- Dashboard with program selection and operations management buttons

- Machine and network connectivity check

- Barcode scanning and automatic item data fetching

- Product inspection phases and errors displaying

Build digital soliton to streamline your production workflow

Business First

Code Next

Let’s talk

Building long-term relationships

With a track record spanning 18+ years and over 500 projects delivered, we’ve earned the unwavering trust of our clients.

Custom manufacturing software for your niche

CodeIT specializes in tailored manufacturing software, covering many areas of expertise.

Food & beverages

Use niche-specific software to manage ingredients, comply with safety regulations, and generate nutrition labels/expiration dates.

Medicine

Enable item serialization and compliance checks with pharmaceutical industry regulations. Run laboratory tests and track results.

Personal care

Inspect created items and manage product labeling and packaging. Create custom programs to produce personalized items.

Tools & instruments

Enable precision size measuring, detect manufacturing defects, and manage inventory.

Packaging materials

Manage packaging materials, create and print labels, and track material usage in live time.

Clothing

Track apparel inventory and check fabric quality. Collaborate with external e-commerce software to create custom products.

Manufacturing software trends

Boost your business with the latest tech trends. Incorporate industry 4.0 technologies with CodeIT.

Industrial internet of things (IIoT)

Control and monitor machines and premises by using smart devices connected to one network.

- Remote device management

- Asset tracking

- Predictive maintenance

- Product quality control

- Manufacturing automation

Cloud computing

Establish a serverless infrastructure to enable remote access to your custom manufacturing software.

- No physical server maintenance

- Remote access over the Internet

- Data backup and recovery

- Seamless scalability

- Top-tier security

Big data & analytics

Optimize manufacturing processes with data-driven insights mined from the collected data.

- Predictive maintenance

- Resources usage optimization

- Product quality check

- Product line analytics

- Risks identification

AI & ML

Detect repetitive patterns, identify anomalies, optimize processes, and enable computer vision.

- Demand forecasting

- Anomalies identification

- Natural language processing

- Computer vision

- Product quality control

Augment reality (AR)

Design product prototypes, enhance labor force productivity, and improve employee training.

- Training and upskilling

- Machinery arrangement design

- Virtual product presentation

- AR-driven guidance

- Remote technicians training

Blockchain technology

Enable top-tier security, advanced item traceability, and verify product authenticity.

- Quality control

- Item movement tracking

- Product authenticity check

- Smart contracts

- Product recall management

Solve your production problems?

Business First

Code Next

Let’s talk

Development services for manufacturing: in stages

The manufacturing software development workflow comprises crucial stages. They help clearly identify project goals and develop the solutions your business needs.

First contact

Reach out to start a conversation about your project. Our team is ready to ensure a smooth and secure collaboration.

- Submit your request

- Get in touch with us within 24 business hours

- Sign a non-disclosure agreement (NDA)

- Share business vision and project details

Planning and analysis

Collaborate to understand your project needs and define a tailored approach for effective manufacturing software development.

- Analysis of received project and technical requirements

- Solution architecture development

- Tech stack selection

- User role definition

- Definition of done (DoD) description

- Key performance indicators (KPIs) definition

- Tasks backlog creation

Design

We design user-focused solutions that align with your manufacturing goals and reflect your brand identity.

- Business requirements analysis

- Wireframes creation

- User interface creation

- Change request processing

Development and testing

Our software engineers help transform ideas into functional solutions, starting with a prototype and progressively enhancing features to meet evolving needs.

- Sprint planning and implementation

- Minimum viable product (MVP) development

- Iterative feature development

- Code review

- Product and increment testing

Deployment

We launch the finalized product on a reliable infrastructure, ensuring comprehensive support and documentation.

- Infrastructure configuration

- Minimum viable product release

- Incremental feature release

- Technical documentation creation

Maintenance

Get ongoing support to address evolving needs and maintain optimal product performance.

- Post-release product support

- Unforeseen issue troubleshooting

- Change requests processing

FAQ

Manufacturing software helps enable automation and process visibility, operate product line machines, and solve industry-specific problems. The manufacturing software comprises a large variety of digital solutions, including:

- Manufacturing execution systems

- Machine monitoring software

- Production planning software

- Data mapping tools

- Product lifecycle management systems

By opting for manufacturing software development services, you can create custom software for achieving your business goals and solving critical issues. Also, it helps unlock the full potential of your business and incorporate modern technologies to outperform competitors.

Digital solution development for manufacturing companies helps businesses develop unique systems for solving mission-critical problems and driving innovations.

The five core benefits of incorporating tailor-made manufacturing software are:

- Improved productivity

- Reduced costs

- Increased processes visibility

- Better product quality control

- Strengthened security

The two major options are as follows.

- Custom software development and integration. A new solution is created from scratch and released as a dedicated application.

- Existing solution re-engineering and upgrading. The tech stack of the existing software is analyzed, and new functionality is developed. New modules are integrated into the existing software to enrich its functionality.

The primary issues that businesses face when implementing new manufacturing software include the following:

- Out-of-shelf software: vendor lock-in, limited functionality, integration limitations, lack of data control.

- Custom-built solutions: technology selection, features development prioritization, data migration.

Our manufacturing software development services help develop solutions that fit your business needs perfectly. Additional benefits include:

- access to industry expertise

- perfect-fit feature set

- rich integration capabilities

- scalability and customization

Our company helps create custom digital solutions to real business problems. The foremost challenges that software includes the following:

- Limited machine interoperability — the usage of diverse different data formats by machines.

- Equipment downtime — unforeseen production disruptions caused by machine failure.

- Poor visibility — lack of real-time shop floor data that is collected on the main server.

- Supply chain disruptions — poor inventory management and planning that leads to stockouts/overstocking.

- Insufficient quality control — lack of monitoring solutions for automated quality control for manufactured goods.

- Manual program configuration — the manual check of machine status and program configuration & scheduling.

- Lack of insights — insufficient data analysis practices that cause poor insight extraction.

- Regulatory requirements violation — lack of tools for monitoring regulatory compliance.

- Cybersecurity threats — insufficient cybersecurity and data protection practices.

Business First,

Code Next.

Let’s talk

Manufacturing software you need—developed your way. It’s time to revamp your production.