Machine Uptime Monitoring Software

Industry

Manufacturing

Location

USA

Partnership period

2019 – 2020

Team size

5

Project information

About Client

The client is a top company with a 30-year experience in providing manufacturers with the right data for monitoring their product lines. It offers a broad variety of tools combined in the manufacturing execution systems (MES) cluster.

MES software helps manufacturers:

- Improve the availability of data

- Decrease machine downtime

- Lower costs

- Improve decision making

- Reduce paperwork burden

Our Task

The CodeIT team was involved in the project as an experienced tech vendor. Our team was assigned to create a new machine uptime monitoring tool and connect it with the existing manufacturing execution system.

Our team was requested to develop new software to help:

- Monitor the current program of machines

- Analyze data and generate charts

- Present relevant information on a dashboard

- Prepare reports automatically

- Check and configure system permissions

Implementation

CodeIT has decomposed the machine uptime monitoring software development process into six stages and defined outcomes for each.

Analysis and Technology Selection

We’ve thoroughly analyzed project requirements received from the client to understand the problems it should solve and define the scope of work. Also, our team has examined the existing manufacturing execution system to pick the right technologies for implementing new software.

Product Development Planning

The CodeIT team has decomposed the machine uptime monitoring software development task. We’ve created a backlog of tasks, defined outcomes, and identified risks to tackle. The detailed plan enabled consistent and bottleneck-free software development.

Team Onboarding

We’ve onboarded a team of tech experts with the required skills to implement the requested solution. CodeIT has identified roles and responsibilities, created a communication plan, and defined tools.

Solution Development

The CodeIT team has created front-end and back-end machine uptime monitoring applications. We’ve also created a database and configured an Apache server. The foremost components developed by our team are the following.

Testing and Optimization

Our quality assurance (QA) specialist has executed manual and automated tests.

Also, we have optimized the developed solution by minifying the CSS and JavaScript code. The minification has helped our team increase the system’s performance.

Software Integration

The tested and optimized machine uptime monitoring software had been integrated into the existing manufacturing execution system. Besides, we’ve tested the integration to ensure the software works error-free.

Need complete shop visibility in one place?

Business First

Code Next

Let’s talk

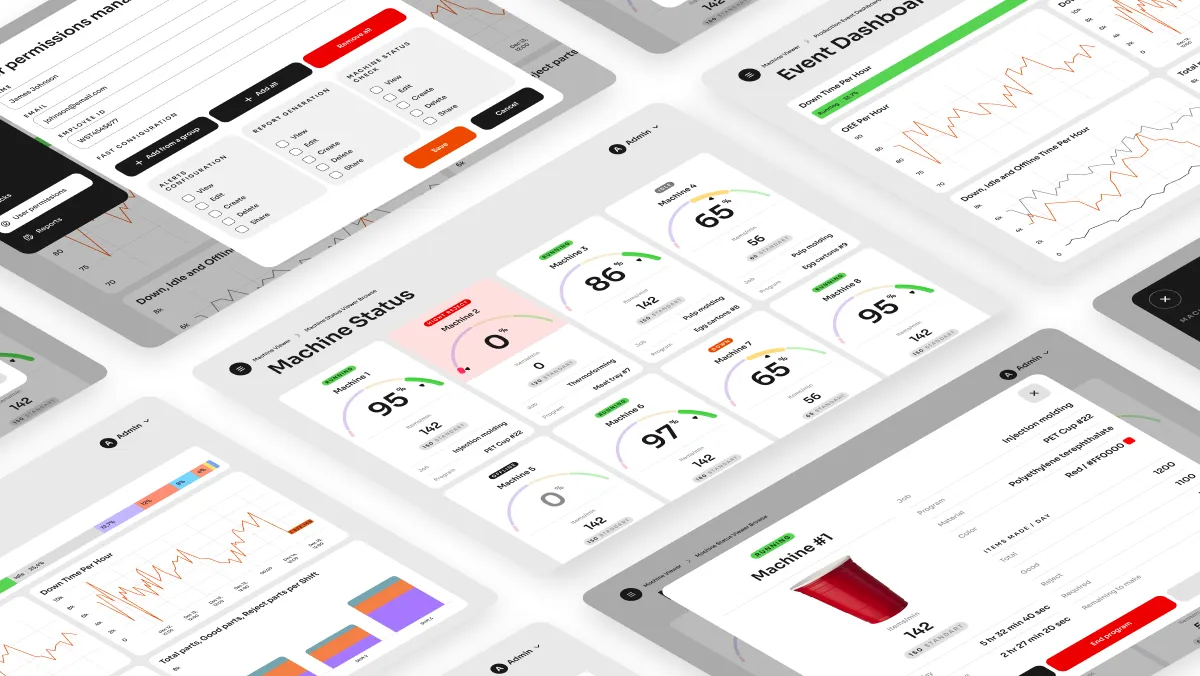

Features implemented

The core functionality of the developed software unlocked the opportunity to monitor all the processes using a single solution.

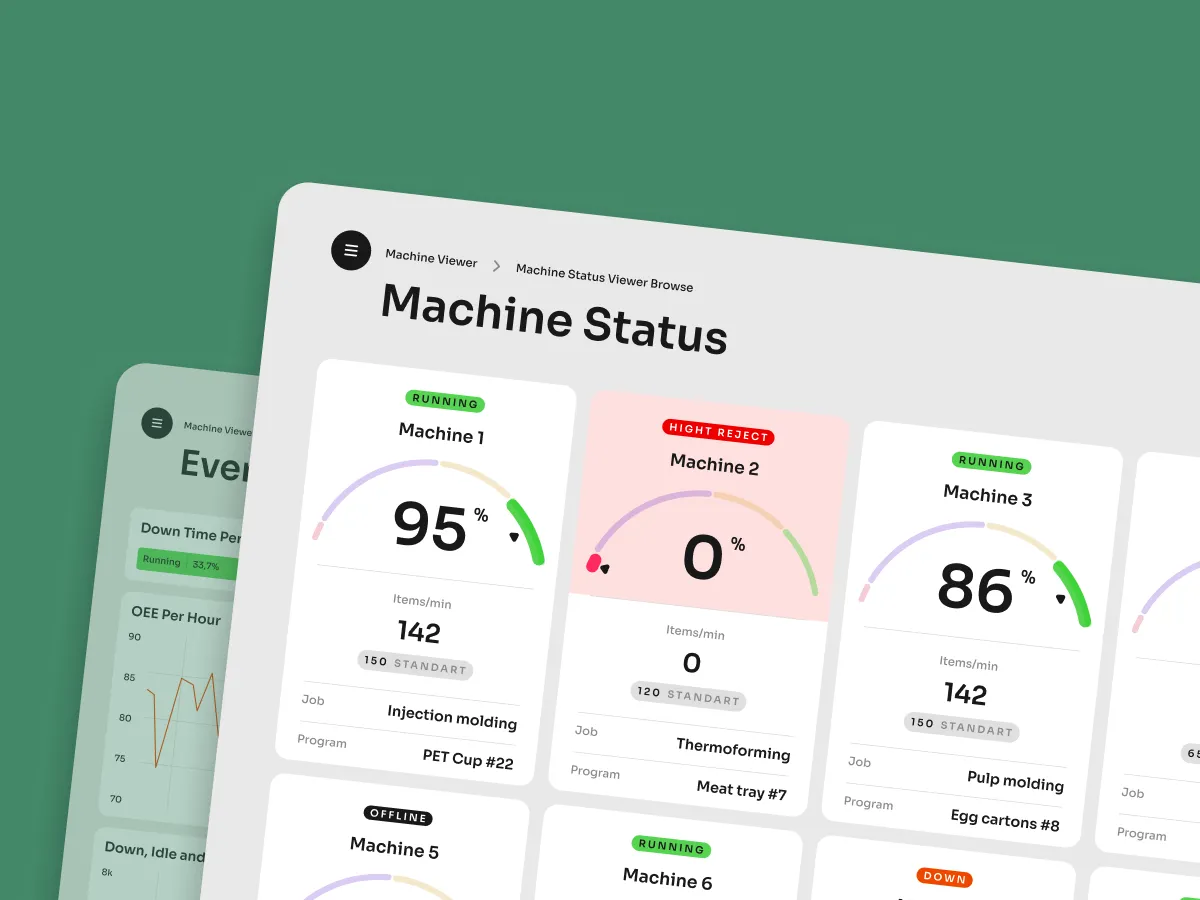

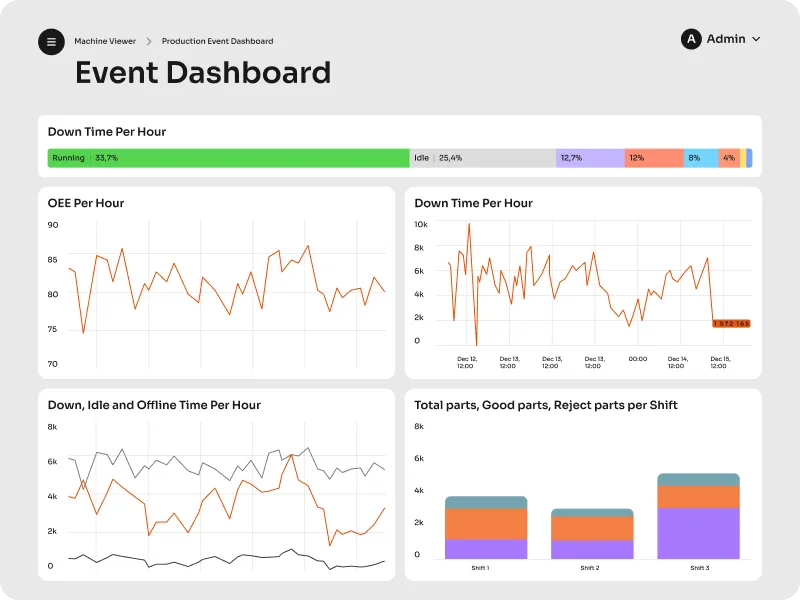

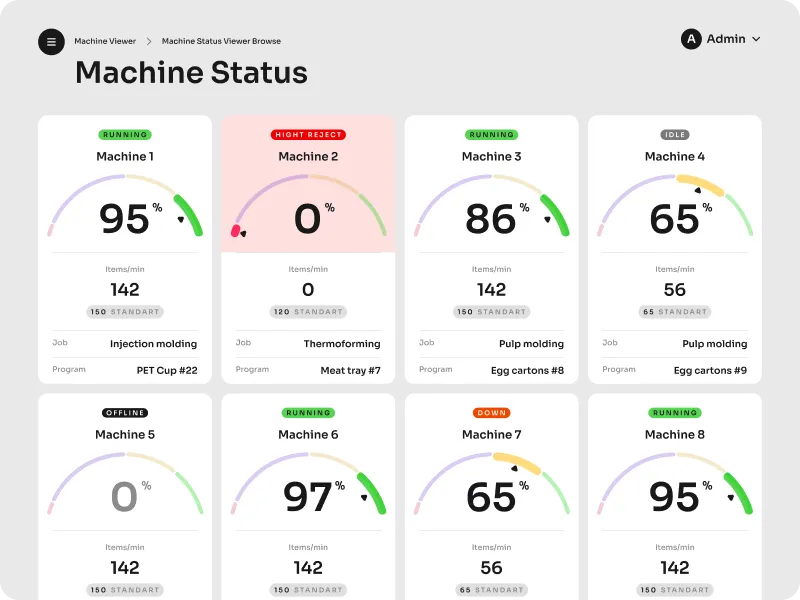

Dashboard

A web app that provides access to relevant information about product line machines, including the following:

- Machine uptime

- Product quality

- Shop floor productivity

- Job summary

- Material usage

All the data is gathered and analyzed in live time. Users can create custom dashboards by rearranging the order of displayed information to access the most relevant information first.

Data Visualization

The system analyzes and transforms all the data received from machines to make it easy to consume for end users. The developed system automatically generates charts and updates them in live time once new data from machines is received.

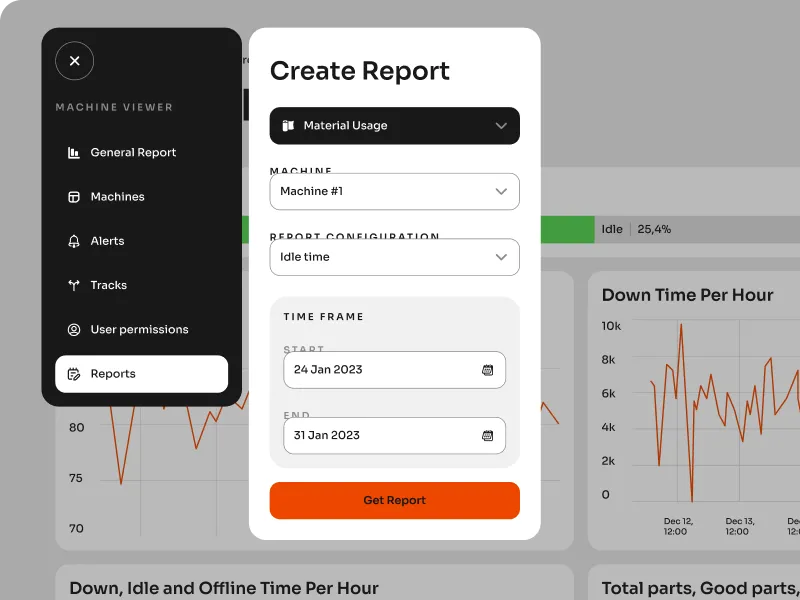

Reports Generation

The machine uptime monitoring software enables the opportunity to generate reports to track the changes in crucial metrics. Users can generate reports for defined periods or enable automatic report generation following a custom schedule.

The rich functionality of the report generation tool foresees the opportunity for users to generate different types of reports containing various information automatically.

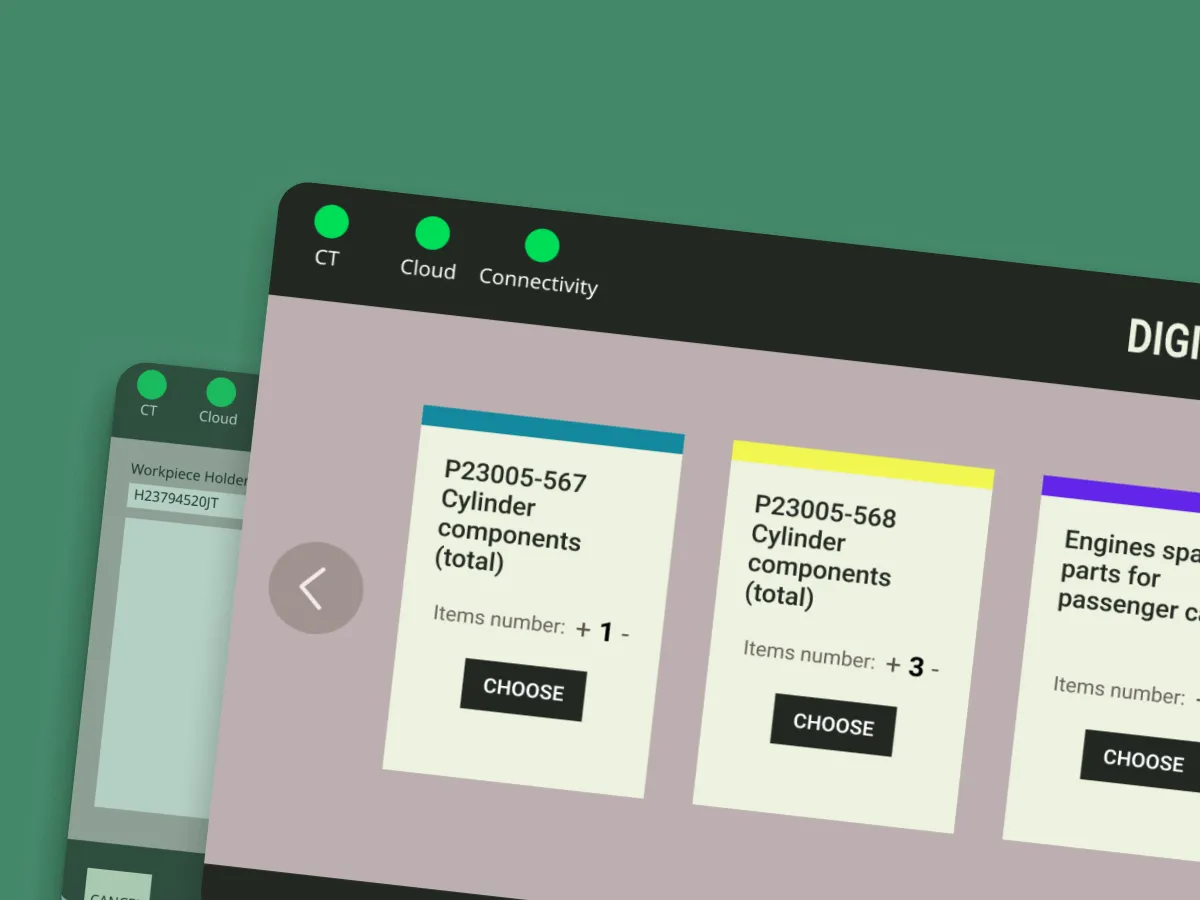

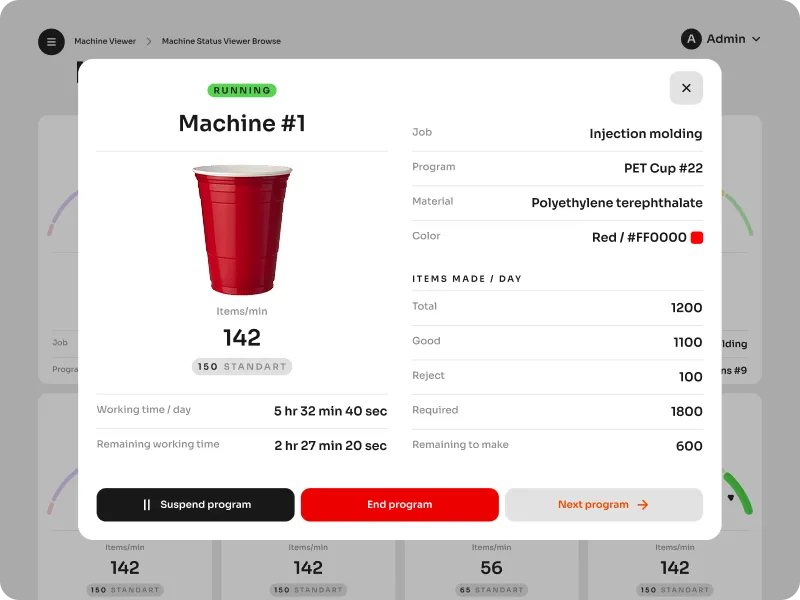

Machine Status Viewer

Users can explore the list of machines in a product line and check whether they are active. Also, they can check the current machine program by clicking on it in the list.

Besides, users can end/suspend the current program of a machine or enable the next program in a queue by clicking a button.

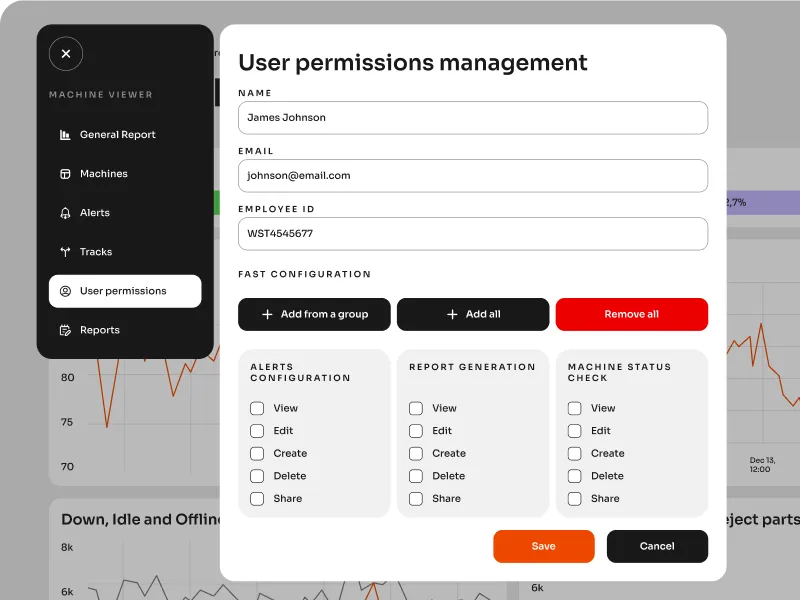

System Permission Configuration

The machine uptime monitoring software users have different permissions that the admin users assign. The permission configuration setting enables the opportunity to limit functionality and data access for defined users. Users who need access to restricted data or functionality can submit requests to the admin user for further approval.

Result

A machine uptime monitoring software integrated with the existing MES.

The CodeIT team has analyzed the existing software, picked the right technologies, composed a product development plan, and created a new machine uptime monitoring software. Also, we have connected the new software with the existing manufacturing execution system to enrich its functionality.

The machine uptime monitoring software developed by our team has helped increase machine management efficiency by 30%.

Services

- Business Analysis

- Web Development

- Custom Development

- Quality Assurance

- Project Management

Team

- Business analyst

- Project manager

- Back-end developer

- Front-end developer

- QA engineer

Technology stack

- HTML

- SCSS

- JavaScript

- jQuery

- Python

- Django framework

- PostgreSQL

- Apache

Related cases

Explore related services

Business Analysis Services

Conduct thorough research to build a solution that drives results.

Web Development

Create online apps that work seamlessly across all devices via the Internet.

Custom Software Development

Implement custom features designed to solve your unique business challenges.

Quality Assurance Services

Achieve flawless performance and release bug-free software with rigorous testing.