Machine Learning in Supply Chain

Machine learning (ML) is one of the most promising technologies due to its multiple capabilities that are important for business success in making accurate predictions and recognizing patterns.

What Is Machine Learning In Supply Chain?

Machine learning is applicable in training computers to imitate human thought processes. It generates accurate solutions quicker, even when faced with vast amounts of data.

The technology begins with two sets of data:

- Training Data — It is used to teach the machine to review the data’s correlations while creating a mathematical model afterward

- Test Data — It is the dataset needed to be analyzed as it includes unknowns that must be analyzed for further evaluation

The data is used to train and estimate a selected model, which is the core output of ML integration. A model can process different types of data and provide correct answers.

With ML, patterns in supply chain data are detected quickly through algorithms that obtain significant factors to the supply networks’ success.

Machine learning algorithms can consume many different data types and analyze them to give answers. The technology uses models it develops during the training process.

For instance, using machine learning in supply chain management, businesses can build applications that can do the following:

- forecast demand

- recognize packages

- detect misplaced items

- improve logistics operations

- prevent fraud

- manage automated guided vehicles

- detect errors

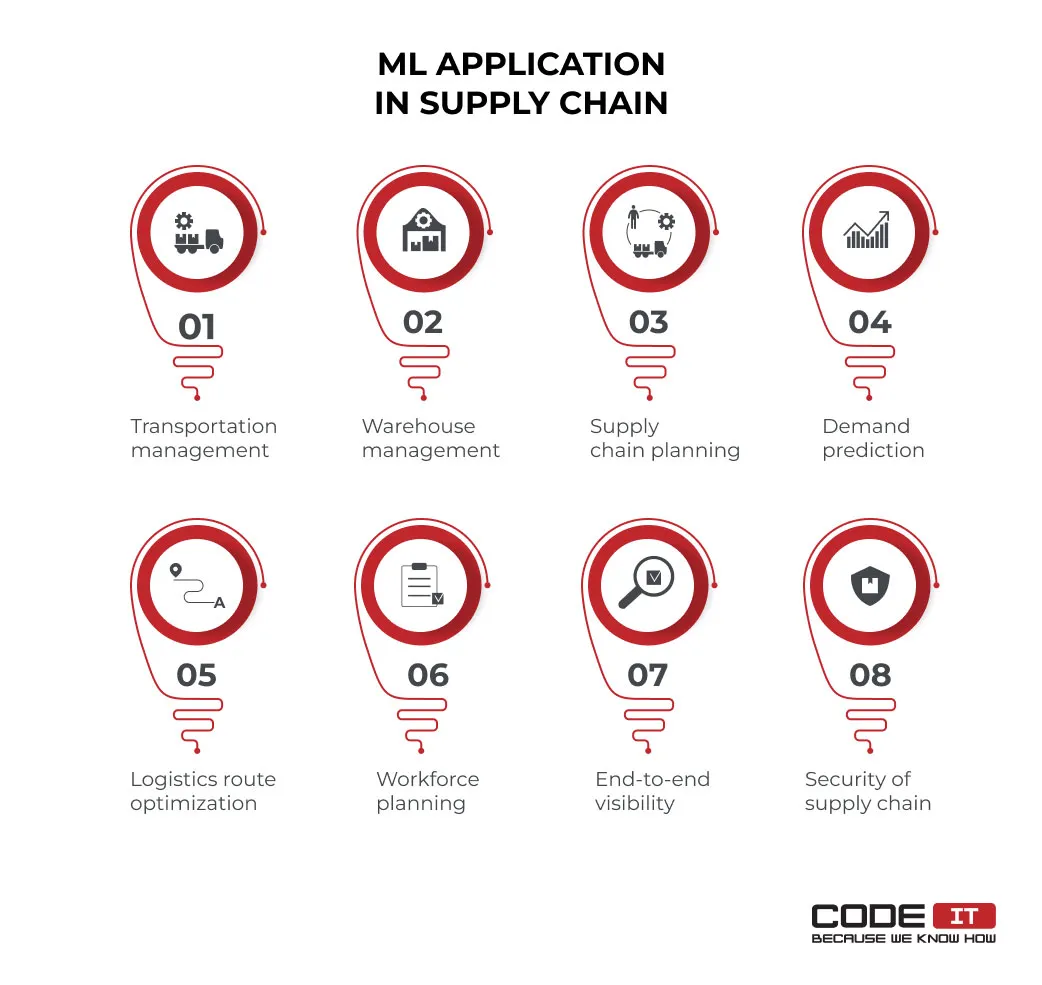

Machine Learning Application In Supply Chain

In keeping a successful and profitable business, it is necessary to ensure that challenges and problems in the supply chain are addressed and solved quickly, mistakes are avoided, and future opportunities are predicted as accurately as possible.

Implementing AI and machine learning algorithms in the supply chain for your business proves to be a success in the following cases.

Transportation Management

Companies actively acquire transportation management systems to promote freight savings and provide a more competitive service while determining the impact on performance.

Machine learning allows companies to access potentially insightful data and discover answers to questions about the company’s performance:

- Do you meet service level standards in terms of delivery and schedule?

- Which lanes are associated with more delays in the service?

- What bottlenecks cause shipment delays?

Having all this information, a company can find solutions to conflicts in the future as machine learning promotes high service levels and a better understanding for shippers on how to deliver results efficiently.

Warehouse Management

Machine learning in the supply chain industry provides more accurate inventory management that helps predict demand. Machine learning is used in warehouse optimization to detect excesses and shortages of assets in your store on time.

This is essential in preventing sales losses due to the ability to pinpoint familiar patterns, inspect storage, and check the inventory now and then in a more accurate way.

Supply Chain Planning

Using machine learning in supply chain planning makes decision-making processes optimized by applying AI algorithms to analyze massive data sets. The adoption of machine learning techniques in supply chain management leads to ensuring more comprehensive planning functionality, producing accurate results, and making it a powerfully reliable tool.

Demand Prediction

Machine learning-powered demand prediction algorithms provide improved demand forecasting. By analyzing customer behavior tendencies, businesses can easily match potential buying habits and precisely shape the customer portfolio.

Being capable of forecasting demand in supply chains using machine learning algorithms, companies can control manufacturing and logistics in the prevention of supply shortages and excesses.

Logistics Route Optimization

It is essential to incorporate machine learning techniques for route optimization, which analyzes existing routes for faster delivery of goods. Enabling this function also prevents delivery delays and helps enhance customer satisfaction.

Workforce Planning

By using existing production data, machine learning can create a more appropriate environment that can naturally adjust to various condition changes in the future. It applies to recruitment, retention, employee development, and performance management.

Automating the processes of gathering data, making inferences, and generating ready-to-use insights can be done when machine learning is utilized in workforce management. Thus, managers get reliable tools for maximizing the overall workforce performance when using machine learning in supply chain management.

End-to-End Visibility

Machine learning algorithms used in supply chains play a crucial role in providing end-to-end visibility from suppliers and manufacturers to stores and customers and eliminating the probability of conflicts as the technology can accurately identify inefficiencies that require an immediate response.

With machine learning to analyze this data, hidden interconnections between various processes in supply chain management can be discovered without fail.

Security of Supply Chain

Your company must have intelligent and complex security to avoid illegal infiltrations that may harm data within the supply chain. Machine learning algorithms can evaluate risk factors by simply using data of those trying to access information, what kind of information they’re trying to access, and from what type of environment the request is coming from. A data privacy breach is prevented if your supply chain is secured with this technology.

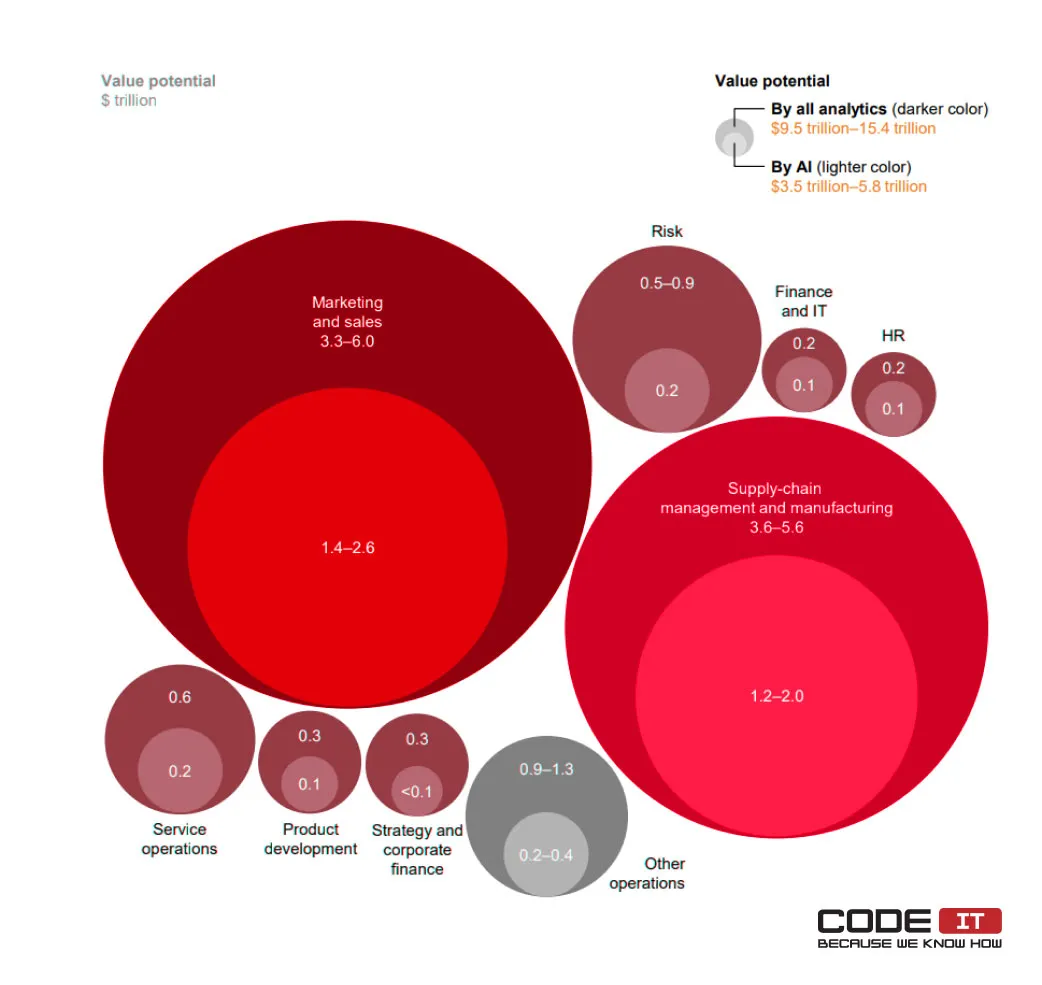

Machine Learning For Supply Chain Statistics

The use of technology has a significant impact on many industries, including supply chain management. According to the artificial intelligence and machine learning in the supply chain case study of McKinsey Global Institute, the industry is highly impacted by these technologies. Let’s check the statistics in more detail below.

Advantages Of Machine Learning In Supply Chain

The use of artificial intelligence and machine learning in supply chains can be applied in different ways. The six main advantages of the technology are:

Enhanced Productivity

Al significantly increases productivity in the warehouse, particularly for online retailers, due to the automatic computation of better solutions.

For example, the technology can analyze the existing workflows and offer suggestions for improving the productivity of the labor force, storage facilities, transportation, etc.

Improved Communication

Warehouse employees and supervisors have to communicate with one another promptly to respond to changes or disruptions. The implication of AI and ML enables effective communication between people and software.

Efficient Warehouse Management

The benefits of integrating machine learning in supply chain management help build fully-automated warehouses, enhancing inventory management and warehouse maintenance.

Reduced Labor Force Costs

Al- and ML-enabled resource planning leads to lower personnel costs or higher reliability. The technologies offer the opportunity to manage the labor force effectively, increasing workers’ productivity and decreasing idling time.

Advanced Robotics and Automation

Robots controlled by Al significantly reduce the number of pickings and travel time for goods in a warehouse.

Improved Warehouse Stock Management

ML-enabled stock planning helps optimize inventory management to store the required items to satisfy the inconstant demand.

The supply chain industry adopts many new technologies that force recent changes. Nevertheless, it can face several challenges, such as:

- fluctuation in demand

- inadequate inventory planning

- backlogs of orders

- uncertainties in logistics

- communication gaps within the supply chain

- shortages in supply

Advanced technologies like machine learning as a branch of artificial intelligence are the optimal solution for addressing these business issues across various industries.

However, it is important to know that though machine learning is versatile, it is not a general-purpose solution that can be used in all data. Instead, machine learning can only successfully work in cooperation with skilled data scientists and business leaders for accurate data selection and validation.

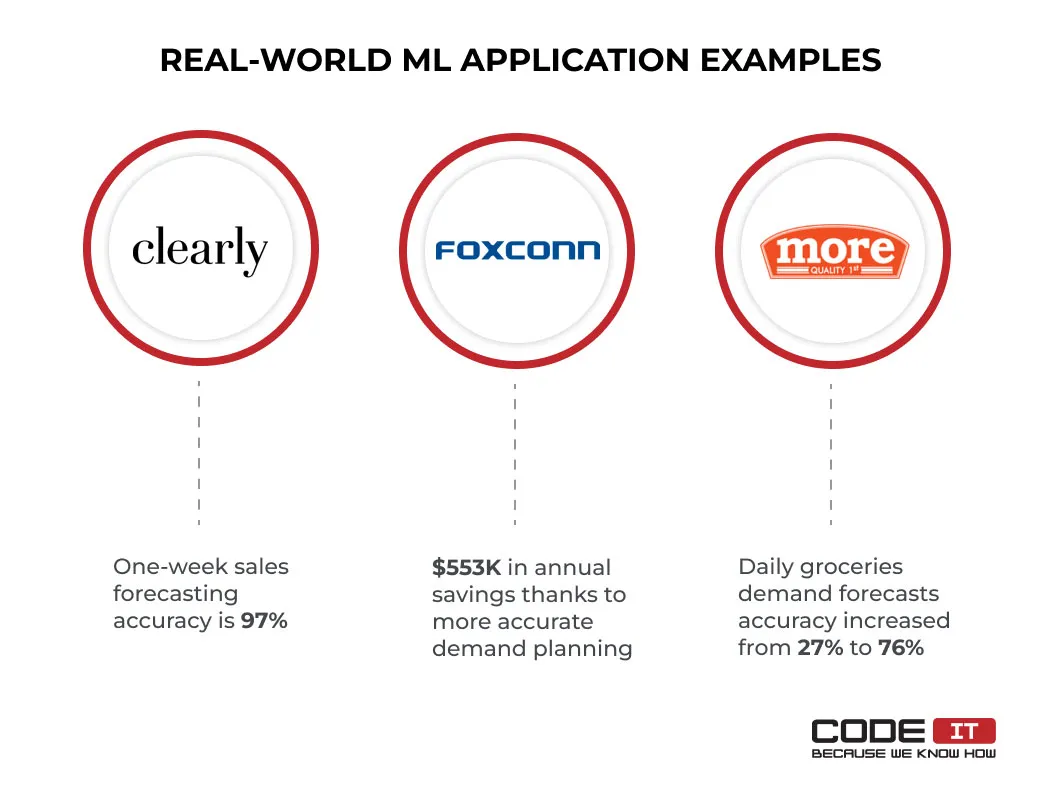

Real-world Machine Learning Applications In Supply Chain Management

Top companies widely adopt machine learning and artificial intelligence in supply chain management due to the many benefits of the technologies.

The three real-world machine learning in supply chain case studies are:

Clearly

The industry-leading eyewear retailer was seeking innovative solutions to solve one of the foremost challenges it experienced. The company needed to predict customer behavior to improve its goods storage and transportation operations.

With ML’s help, the company achieved significant sales prediction results. One-week sales forecasts are 97% accurate. One-month sales prediction results generated with the help of machine learning are 90% accurate.

Foxconn

It is one of the largest hardware production companies that highly relies on its supply chains. The company needs to produce the required number of products to meet the ever-changing demand.

During the Covid-19 outbreak, the company experienced unexpected volatility in customer demand. Hence, the company’s technical advisor adopted ML to process collected data and forecast customer demand.

The solution has helped the factory located in Mexico achieve $553K in annual savings with the help of increased planning accuracy. The result obtained by the company is one of the top machine learning use cases in the supply chain.

More Retail

The #1 Indian food & grocery retail aimed to adopt new technologies to meet the demand for fresh products and decrease wastage.

The company has adopted machine learning in the retail supply chain to analyze data gathered by stores all across the country and build daily forecasting models.

It managed to increase forecast daily accuracy from 27% to 76% with the help of the solution. In essence, it managed to reduce the wastage of groceries by 20% thanks to enhanced forecasting accuracy.

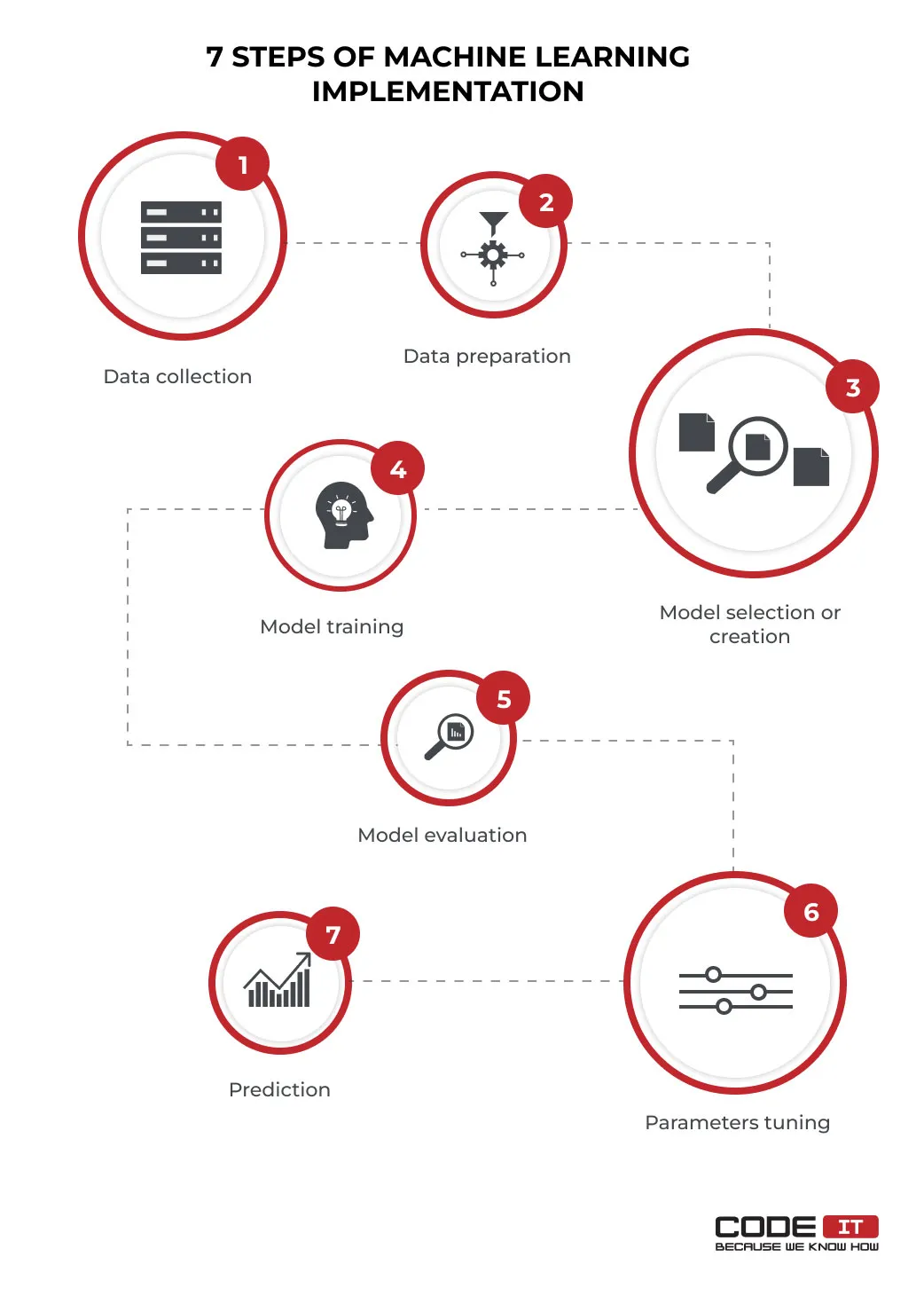

How To Start Using Machine Learning For Supply Chain

There is no multipurpose, out-of-the-box ML solution to enhance supply chain management.

Businesses need to involve tech specialists to train ML models that give correct answers to start using the technology. Software engineers should have linear algebra, data modeling, and statistics expertise. Python is the most popular programming language for building machine learning-driven solutions for the supply chain.

The seven required steps to start using machine learning in supply chain management are the following:

1. Data Collection

For starters, developers need to collect data that will be used for training models to deliver accurate results.

Machine learning algorithms used in supply chains can process different types of data, including images, numbers, text, dates, etc. Collecting large amounts of data is advisable to increase the accuracy of results delivered.

2. Data Preparation

For starters, it’s necessary to randomize all the data for further model training. Also, developers may be required to adjust the data, fix errors, remove duplicates, etc.

Finally, they need to split all the data into two sets: training and testing. Usually, the training data share ranges from 70% to 80%. It’s required to ensure that the model won’t pass the test using the information already processed.

3. Model Selection or Creation

Many different models that serve various purposes were created. ML experts must choose the best one to help achieve the set goals best.

If there is no suitable model, developers can create a new one from scratch.

4. Model Training

The incremental process helps train the model to deliver the correct results. In every iteration, the model can learn to provide more accurate results.

5. Model Evaluation

The testing data is used to check the accuracy of the answers that the trained model can deliver.

6. Parameters Tuning

At this stage, developers should adjust parameters to increase the accuracy of the results that the trained model produces. The parameters adjustment process needs software engineers to experiment with different values to achieve the best results.

7. Prediction or Answer

It is the final step of implementing machine learning in the supply chain. Businesses can get accurate results using the trained and adjusted model supplied with a new data set.

Helpful Tips On Using Machine Learning For Supply Chain

The use of machine learning in supply chain management should be approached carefully. Here are some useful recommendations to help you succeed using the technology.

Set Clear Objectives

Despite the fact that there are a lot of machine learning applications in the supply chain, the implementation of technology must be accompanied by clear objectives.

The very essence of technology implies that you cannot act at random here. Therefore, it is very important to establish clear and understandable KPIs and metrics, upon the achievement of which the success of the implementation will be assessed.

Carefully evaluate the supply chain dataset and its performance before and during the implementation of machine learning in logistics.

Have a Strategic View

Despite the fact that it is difficult to grasp machine learning for supply chain forecasting, the prospects for technology in this segment are extremely high.

However, many entrepreneurs see competitors’ results and strive to create a solution that solves a specific business problem quickly. This is not an entirely correct approach since it would be much more logical to develop a self-correcting system that can learn, grow smarter, and will function in the future to solve similar and new problems.

It is necessary to create the most autonomous AI in logistics and supply chain solutions that will not depend on the constant involvement of specific technical specialists.

Stay Original

Even though there is a sufficient number of machine learning in supply chain case studies in the segment, we advise you to always focus on your specific business needs, audience, and business logic. Not always an original approach will help to achieve success, but blind copying of competitors’ solutions is guaranteed not to give results in a broad perspective.

Concluding Thought

Machine learning in supply chain management enables computing models to adjust to certain conditions, changes, and developments in a business environment with the ability to improve over time.

Aside from that, machine learning algorithms discover new patterns in supply chain data with very little manual interference while still providing accurate information and prediction that helps the business.

By developing ML-enabled logistics software solutions, supply chains are presented with improved accuracy in different branches of their business, such as logistics, operations, planning, and workforce.

Develop a unique solution using machine learning with CodeIT!

FAQ

Machine learning is a technology that helps process large amounts of data. It comes in handy when conventional algorithms and spreadsheets are useless.

With ML, businesses can develop a trained model that provides data-baked answers to questions. Demand forecasting is one of the most widespread machine learning applications in supply chains.

The machine learning model creation implies seven crucial steps that are:

- Data collection

- Data preparation

- Model selection

- Model training

- Model evaluation

- Parameters tuning

- Prediction or answer

With the help of machine learning, businesses that operate in the logistics niche manage to overcome the following challenges:

- fluctuation in demand

- inadequate inventory planning

- backlogs of orders

- uncertainties in logistics

- communication gaps within the supply chain

- shortages in supply

There are many tools and technologies available to build ML-driven solutions. Nevertheless, Python is the most popular programming language for building ML- and AI-enabled software.

Many companies use machine learning to get data-driven insights, predict demand, spot errors, etc.

Some successful machine learning in supply chain case studies are the following:

- Clearly — 97% one-week sales forecasts accuracy

- Foxconn — $553K in annual savings for one factory in Mexico

- More Retail — 49% forecast accuracy increase of daily demand in groceries

Related services and industries

Logistics Software Development

Get solutions designed to streamline operations

Build your ideal

software today