Forecasting in Supply Chain — Best Methods, Tools, and Examples

Forecasting in the supply chain is the process of analyzing data to predict future changes. Businesses can build short-term and long-term predictions by analyzing historical data, modern trends, and other variables.

Efficient supply chain forecasting helps predict the following:

- Customer demand. It is the most critical metric. Customer demand prediction helps businesses avoid overstocking and running out of products.

- Inventory management. Thorough planning helps manage warehouses to store all the items effectively, using modern technologies for inventory management. Consequently, the most demanded assets can be quickly transferred to the picking and packing section for further delivery without delays.

- Pricing. By analyzing customer demand, competitors, and predicted supply, businesses can forecast the most optimal prices for their products.

- Returns and cancellations. Many factors can affect the number of returns and order cancellations. Comprehensive data analysis helps predict the return and cancelation rates in advance.

- Transportation. The demand for drivers and fuel may be unstable and is widely affected by seasonal events. Businesses can contract the required drivers or resources to avoid delivery delays, being capable of forecasting in supply chains.

- Labor force demand. Usually, demand spikes are tackled by involving more labor force or covering overtime work. Predictive planning helps build well-thought-out schedules to always have the required number of workers involved.

- Manufacturing demand. If a business produces new items, the application of supply chain forecasting methods helps plan the number of raw materials that should be extracted and delivered in advance to satisfy the demand.

Different types of data forecasting help businesses in the logistics niche manage operations effectively and spend resources wisely.

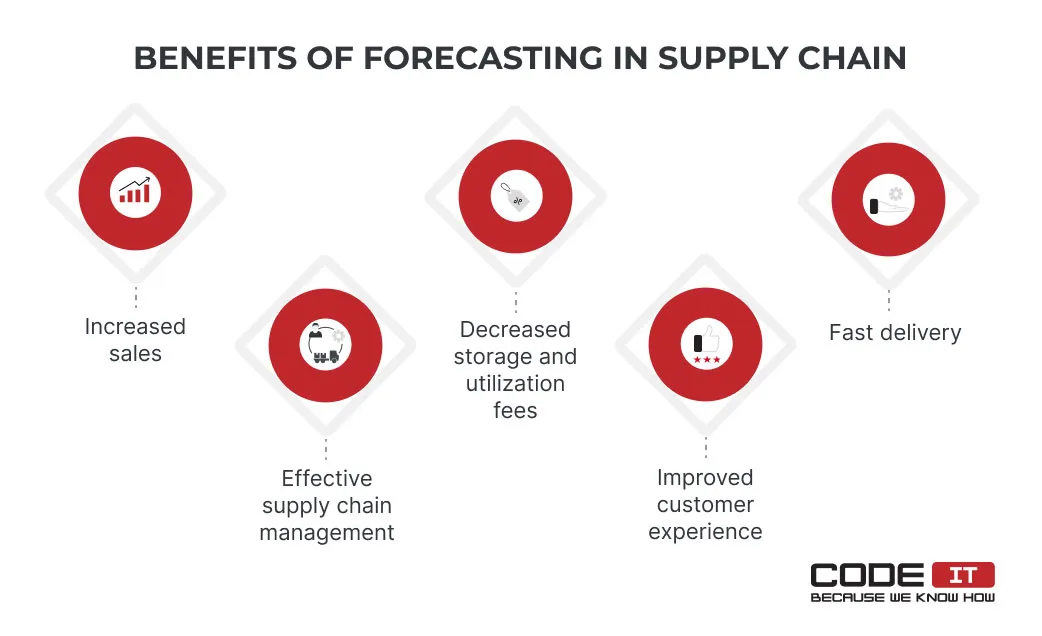

Benefits Of Forecasting In Supply Chain

Accurate forecasting helps cut operational costs, increase customer satisfaction, and enhance inventory planning. Let’s explore the advantages of forecasting in supply chain management below.

Increased Sales

Businesses can increase their sales by having the required number of products ready to ship. In most cases, consumers abandon their carts when products are out-of-stock or cannot be delivered fast.

Hence, businesses lose roughly $1 trillion a year in sales because of the inability to satisfy customer demand, according to RetailDive.

Accurate forecasting can help keep the required number of items in a warehouse to avoid out-of-stock sales losses.

Decreased Storage and Utilization Fees

Due to inefficient planning, warehouses worldwide need to store undemanded products. Businesses are forced to pay fees for storing unwanted goods. Hence, they need to sell products with considerable discounts to avoid storage fees.

When delivering groceries and other perishable products, businesses need to utilize unsold items. Accurate demand planning and forecasting in the supply chain can help decrease storage and utilization fees.

Fast Delivery

These days, customers want to receive products purchased online fast. According to the report prepared by eFulfillment Service, fast shipping is as important as price for customers. A delivery is considered fast when it is fulfilled on the same day or the next day after making a purchase.

Predictive planning, with the help of forecasting in supply chain management, helps businesses keep the required number of goods in their warehouses to deliver purchased products fast.

Effective Supply Chain Management

Sales spikes provoked by seasonal events or unforeseen customer demand changes make businesses run out of stock fast. Seasonal events or unpredictable global changes may force a shortage of labor force, fuel, or materials, which can negatively affect the ability of suppliers to fulfill the demand.

With the help of thorough and data-baked planning, businesses can run their operations effectively. Supply chain management forecasting helps spend resources wisely while satisfying the ever-changing customer demand.

Improved Customer Experience

Customers seek retailers with a large assortment of products that can be delivered within a day or two. Hence, with the ability to fulfill the demand, businesses can provide outstanding customer experiences.

Want to get accurate and data-baked forecasts to optimize your supply chain?

Business First

Code Next

Let’s talk

How Does Forecasting In Supply Chain Work?

The main goal of supply chain planning and forecasting is to predict customers’ behavior by defining patterns in historical data.

Businesses collect historical data and analyze it to define patterns. Also, they conduct research and surveys to gather new information about customer demand.

Different methods and technologies are used to conduct predictive analysis in supply chains.

Supply Chain Forecasting Methods

The two different types of forecasting methods in the supply chain are:

- Quantitative. It uses historical data to define repetitive patterns.

- Qualitative.It uses data gathered from research, surveys, industry experts’ interviews, case studies, and other sources.

Quantitative

Quantitative supply chain forecasting methods widely rely on numbers and statistics. The approach helps measure the following metrics:

- How many/much

- When

- How often

The top five quantitative methods for supply chain management forecasting are:

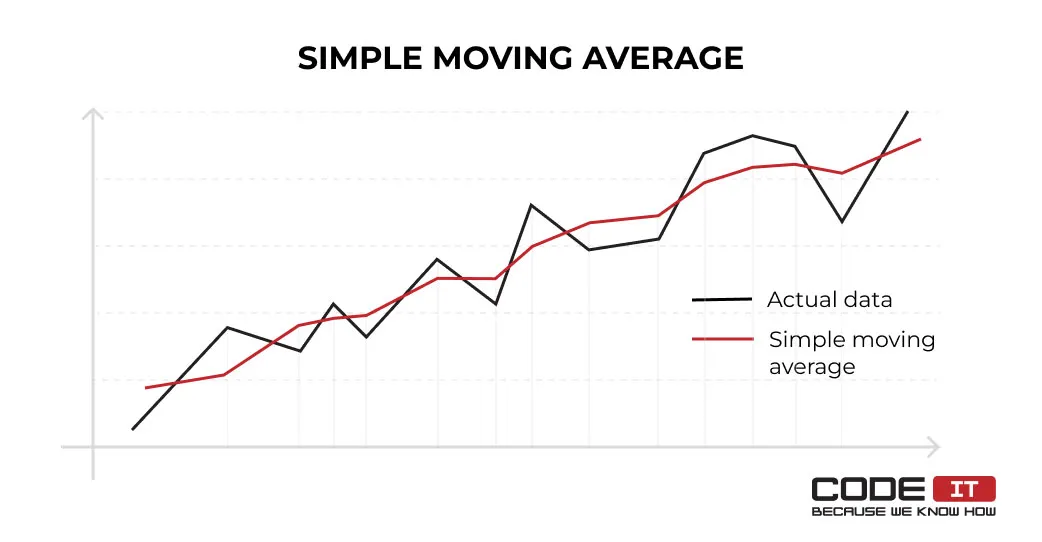

1. Simple moving average

It is the most straightforward method used for forecasting the supply chain. The moving average forecasting method uses historical data to develop intermediate series to predict future demand, sales, resource consumption, etc.

Since the method uses the constant mean, it doesn’t adapt to changing trends, seasonal events, or other factors that affect demand, resource availability, etc. The problem with trend forecasting in the supply chain using this method lies in the fact that the constant mean cannot overcome the average value of data used to develop a predictive model. Hence, the model isn’t good for predicting new trends or seasonal spikes or falls.

In case you want a more accurate forecast that includes recent changes, calculate the average results of a few recent periods using the model.

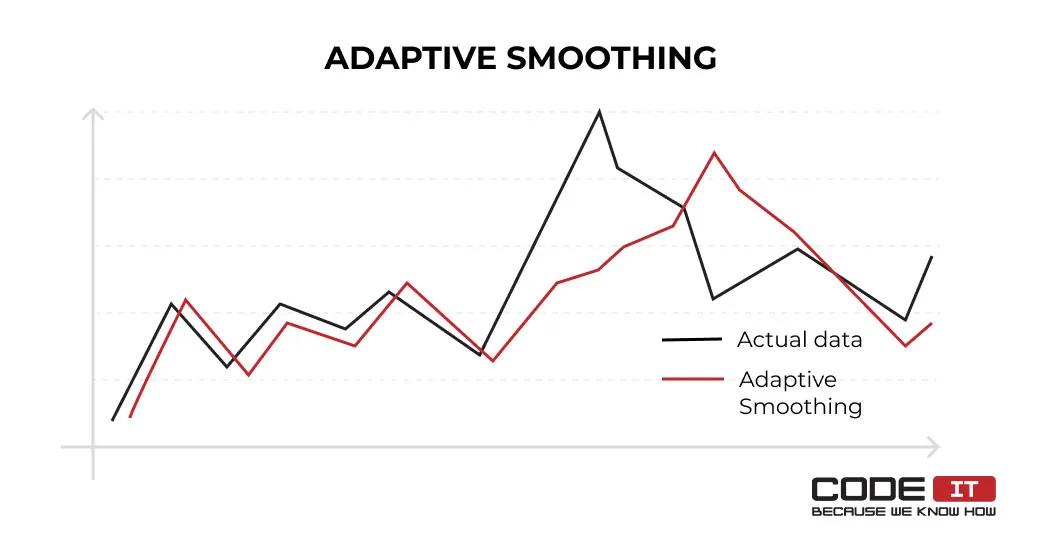

2. Adaptive smoothing

The formula applied in the enhanced exponential smoothing method uses an adjusted variable that changes in accordance with the forecasted and actual results received in every series.

The primary model’s drawback is that it cannot adjust fast in case of significant spikes or falls. The problem is that the method for forecasting in supply chains implies a constant value used to increase or decrease the coefficient used for the models’ adjusting.

Hence, it may deliver inaccurate forecasts if current data experience profound changes caused by seasonality or unforeseen issues.

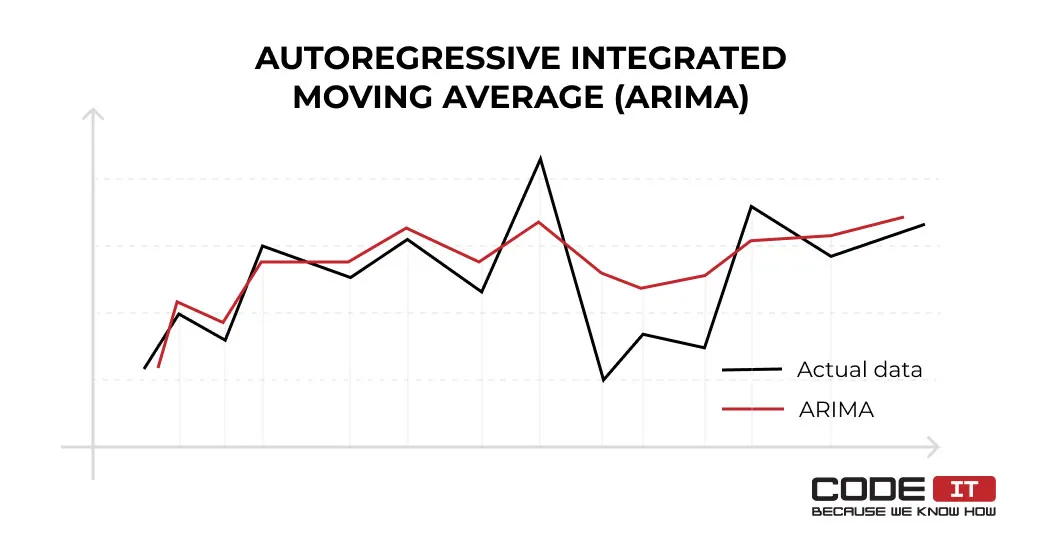

3. Autoregressive integrated moving average (ARIMA)

It is a complicated model that needs to perform plenty of calculations to define the differences between values in data series to build accurate forecasts. The approach applied helps increase the accuracy of short-term predictions.

Yet, the model isn’t good for forecasting seasonality. The seasonal autoregressive moving average (SARMA) model is used to predict seasonal spikes and falls. In a nutshell, the ARIMA predictive model is applied to detect patterns that repeat monthly, quarterly, yearly, etc.

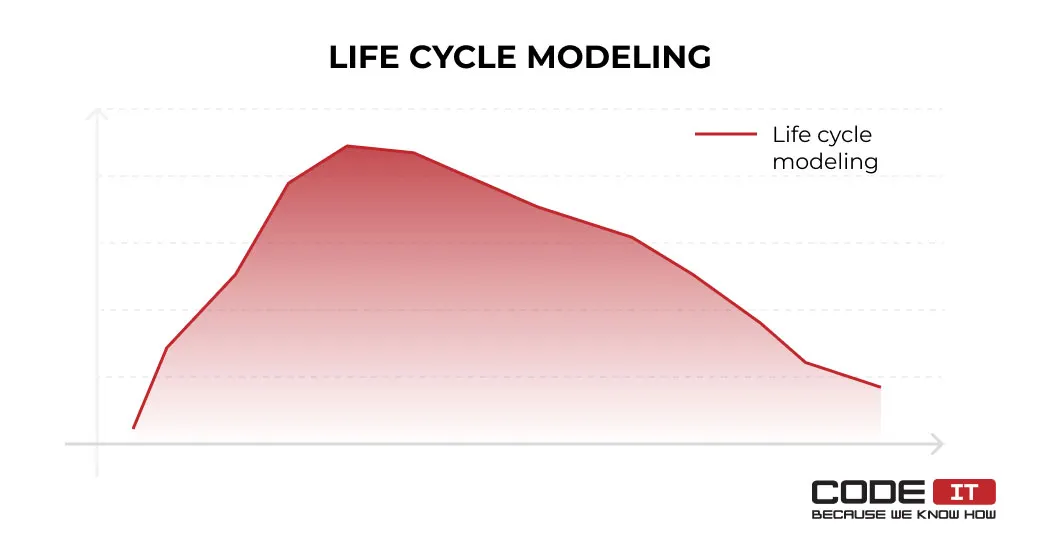

4. Life cycle modeling

The method needs to gather data from different sources like manufacturers, suppliers, retailers, etc. Life cycle modeling helps build long-term forecasts, taking into account many different factors like seasonality, demand, availability of resources, competitors, etc. The method is applicable to forecasting the life cycles of new products.

For instance, popular commodity goods and groceries have flat charts. New tech products experience a steady customer demand fall after fast popularity growth, as presented in the chart above.

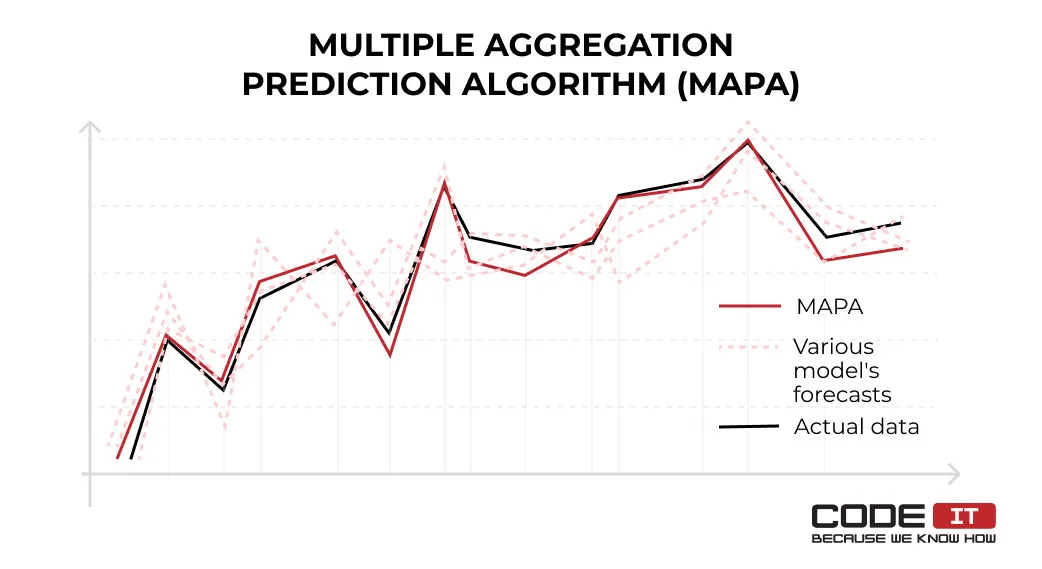

5. Multiple aggregation prediction algorithm (MAPA)

The supply chain forecasting method helps predict changing trends by analyzing multiple time series using machine learning. Since various time series can present different aspects of forecasting, the method combines them using temporal aggregation. The approach applied to building supply chain forecasting models helps achieve better accuracy for long-term forecasts.

The three major stages of supply chain forecasting using the MAPA method are:

- Aggregation — Data series components are gathered

- Forecasting — Time series are analyzed using distinctive models

- Combination — Results are combined

Time Series Forecasting in Supply Chain

Qualitative

The qualitative type of forecasting methods in the supply chain relies on real-world experiences, professional expertise, surveys, and other similar data types.

Qualitative data can help answer the following questions:

- What is your opinion?

- How would you improve it?

- Why did this happen?

Qualitative methods are used for forecasting supply chains when there is no historical data to analyze, or unexpected circumstances affect supply and demand. Therefore, casual qualitative forecasting methods are widely applied to predict the demand for new products or adjust plans affected by unforeseen global challenges, like a pandemic.

The top four qualitative forecasting methods in the supply chain are:

1. Historical analogies

It is a supply chain forecasting technique that needs you to find a similar product sold earlier and analyze its demand. The method is based on the assumption that new similar products will have the same demand.

Historical analogies can be used to build various predictive models. For example, businesses can forecast the percentage of returns, resource availability, pricing trends, etc.

This supply chain forecasting method can hardly help build accurate short-time forecasts. Historical analogies can help develop strategic plans for asset storage and distribution.

2. Panel consensus

The method relies on the opinion of every team member. It’s required to gather all team members in your organization and share equal data.

Ask them to analyze the given data and build forecasts based on their personal experience and expertise. Every team member should share their forecasts and explain to others their points of view.

After this, the entire team should come to a consensus, taking into account all the thoughts and ideas of experts shared during a forecasting session.

The method’s accuracy strictly depends on the amount of data gathered and the industry-specific knowledge of team members.

3. Market research

It is a comprehensive supply chain forecasting method that involves many activities to gauge demand, analyze competitors, or test a product.

The most forecasting techniques in supply chain that help conduct market research are:

- competitor research

- product testing

- loyalty analysis

- buyer persona analysis

- polls and surveys

- field tests

Need to conduct expert-grade market research?

Business First

Code Next

Let’s talk

4. The Delphi method

It is the questionnaire-based method that was initially developed for military action planning. The technique needs a business to gather the following roles:

- experts

- facilitators

It’s required to prepare a questionnaire that implies questions without true answers for accurate forecasting in supply chains. For instance, experts may be asked to share long-term forecasts based on their perspective or share information about possible outcomes of specified actions.

All the questionnaire papers should be submitted anonymously. Facilitators need to assess them and form a collective forecast.

Can I use mixed methods?

Supply chain forecasting methods have distinctive peculiarities as well as weak and strong sides. Hence, different methods should be chosen for various purposes.

You can get the whole picture in a mixed-methods study. Therefore, don’t hesitate to build forecasts using various methods and analyze them.

Some forecasting methods in the supply chain may bring more accurate results when building short-time forecasts. At the same time, other methods may be helpful for strategic planning because of proper long-term planning or deliver valuable insights thanks to using different data sources.

For instance, you can use time series forecasting in supply chain management and apply the Delphi method to get more useful information.

Tools and Technologies

Various tools and technologies can be applied when using qualitative supply chain forecasting methods. For instance, experts can use online surveying tools to collect helpful information or use digital tools to analyze competitors.

The four most commonly used tools and technologies to analyze historical data using quantitative methods are:

1. Manual forecasting

Manual calculations aren’t widely used to build comprehensive forecasts. Small businesses may process low amounts of data manually using a pen and paper to analyze trends and develop predictions.

2. Spreadsheets

Spreadsheets are useful for forecasting in supply chain management if a business generates a limited amount of data to analyze.

Experts can accumulate a lot of data and apply custom formulas using spreadsheets. All the calculations are performed instantly. Also, spreadsheets foresee the ability to build charts to spot trends, seasonal spikes/falls, and other patterns.

3. Third-party software for data analysis

Many companies offer solutions that foresee the ability to upload historical data and get predictions. Usually, such solutions can apply certain algorithms to define patterns and build predictive models.

4. Machine Learning and Artificial Intelligence

Machine learning and artificial intelligence are the fastest-growing technologies applied to develop forecasts. According to the research conducted by McKinsey&Company, 20% of businesses already use the technologies for forecasting in supply chains. Moreover, 60% of respondents are about to adopt ML and AI to build accurate predictive models.

In a nutshell, the technologies help businesses develop self-learning models that can quickly analyze large amounts of data and deliver accurate forecasts.

The seven steps of ML model creation are:

- Data collection

- Data preparation

- Model selection

- Model training

- Model evaluation

- Parameters tuning

- Prediction

The most popular programming language used for supply chain forecasting is Python. It offers access to a large number of libraries and frameworks. Also, Python has a simple syntax that can create complex ML and AI algorithms.

Machine Learning in Supply Chain

How Do I Build Forecasts In Supply Chain?

In the case of using manual calculations, spreadsheets, or third-party software for forecasting in supply chain management, it’s advisable to involve a skilled data analysis specialist. The involved expert should have the required expertise and knowledge for turning raw data into valuable insights using quantitative or qualitative forecasting methods.

If you strive to adopt machine learning in supply chains to develop predictive models, it’s advisable to find an experienced technological partner. It will help you prepare data, pick suitable models, and train them to deliver accurate forecasts in supply chains.

We recommend taking the following steps to build an AI- or ML-enabled solution for forecasting in supply chains.

1. Define Requirements

Receiving outstanding forecasting supply chain results is easier if you have clear objectives.

We recommend analyzing your existing operations to understand what you need to achieve by implementing a new forecasting solution.

Goals should be well-defined to discover whether it is achieved or not. Also, they need to be attainable and relevant to your business.

2. Find a Vendor

Find a trusted partner to implement new solutions for supply chain forecasting.

Feel free to use the Internet to find industry experts or explore trusted listings. The most popular websites to explore are:

With the help of these websites, you can find a broad selection of firms with expertise in extensive data analysis or machine learning.

Shortlist the top-rated agencies with expertise in forecasting supply chains by assessing the following:

- reviews shared by verified clients

- successful projects completed

- workflow and technology expertise

Also, feel free to contact the representatives of shortlisted companies to get your project estimated.

3. Gather Data and Pick a Method

When using qualitative supply chain forecasting methods, a hired vendor should collect all the required information from various sources and analyze it to deliver valuable insights.

If you use a qualitative method, a hired expert can help you do the following:

- Collect historical data using various sources

- Prepare data by formatting it, removing duplicates, and fixing errors

- Configure a cloud server for big data computing

- Choose the best forecasting method to achieve the desired results

- Select the right models for AI- and ML-enabled forecasting

- Train the selected model to get accurate results

4. Test and Implement

Assess the results and implement a new solution for forecasting in supply chains. If the received forecast is inaccurate, adjust the model and iterate.

Also, it’s vital to make a new solution easy to use for end-users who need more technical expertise. A hired vendor can help develop a logistics software solution with a well-thought-out user interface that other team members can use with minimal training.

Machine Learning Outsourcing

Successful Supply Chain Forecasting Examples

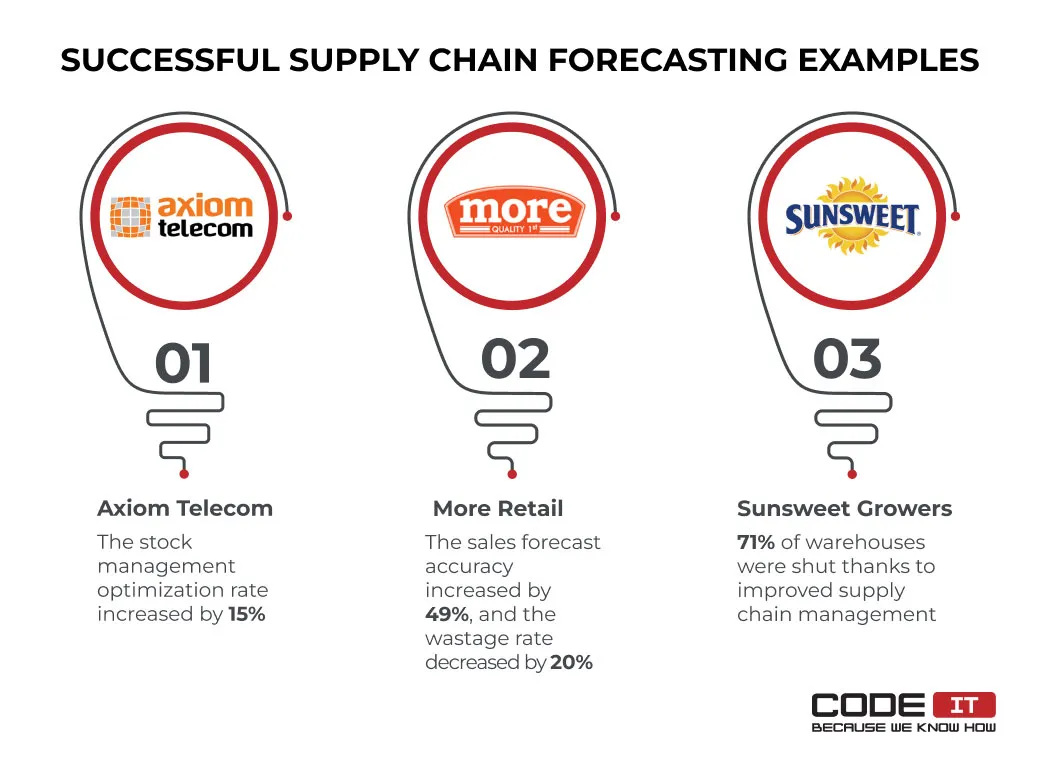

Predictive analysis is widely applied by businesses that operate in the logistics niche. Let’s check the most successful forecasting in supply chain management examples.

Axiom Telecom

The retail company leads the smartphone and other technologies market in the Middle East region. The company relied on manual demand forecasting using spreadsheets to predict customer demand. It was an insufficient planning method because of the need to allocate a lot of resources and poor accuracy.

Hence, the stakeholders decided to switch to using modern technology for supply chain management forecasting.

The company has achieved a 15% increase in stock management optimization by adopting a new digital solution. Having 30 warehouses and more than 300 distribution vehicles helped the company cut many expenses. Also, the firm managed to free up employees involved in manual forecasting.

More Retail

The niche-leading company in food retailing in the Indian market experienced many inventory and delivery issues due to insufficient planning. Since they sell perishable products, inaccurate planning caused a significant wastage rate.

The company achieved significant improvements by integrating a digital supply chain forecasting solution. The company has increased the accuracy of sales forecasts by 49%. The improvement helped reduce the wastage rate by 20%.

Sunsweet Growers

The company manufactures and sells juices and dried fruits. The lack of efficient planning caused high-pitched production costs. Hence, the firm integrated supply chain forecasting tools to predict the demand for their products.

The 20% increase in supply chain forecasting accuracy helped the company to achieve a 100% return on investment. Moreover, it managed to reduce the overtime hours usage rate from 25% to 8%. Thanks to efficient supply and demand planning, the company closed 20 warehouses out of 28 that were running before.

The adoption of comprehensive types of forecasting in supply chain management has helped Sunsweet Growers optimize its processes and cut expenses.

Switch from using spreadsheets by developing an ML-enabled digital solution!

Tips For Improving Supply Chain Forecasting

Having an existing supply chain system, you can implement minor changes to eliminate inefficiencies and improve forecasting using the data you already have access to.

The core five tips include:

- Improve collaboration across the supply chain — Enhance communication between suppliers and distributors to ensure accurate demand planning. Also, data-sharing pipelines can be created to exchange relevant information that can be used to improve forecasting models.

- Analyze real-time data — Don’t rely on historical datasets. Collect and use recent and real-time data to spot new trends and promptly react faster to sudden market changes.

- Leverage AI usage — Apply AI models to analyze the collected data. The technology is capable of detecting hidden patterns and interdependencies.

- Incorporate external factors — Optimize your forecasting models by analyzing external factors that may affect trends. The factors may comprise weather patterns, local events, global trends, macroeconomic data, and more.

- Conduct scenario planning — Prepare for potential disruptions by conducting scenario planning based on different market conditions, such as economic downturns, supply chain disruptions, or sudden demand spikes.

Data Preparation Tips

The accuracy of supply chain forecasting and planning heavily depends on the quality of data analyzed. These five tips will help you ensure your data is well-prepared for further analysis and demand forecasting model development.

1. Standardize Data Formats

Ensure that all data is recorded in defined formats across all data sets. This helps prevent data analysis errors and allows a business intelligence system to interpret the input information correctly.

The data standardization actions may include the following:

- Date and time format changing to ensure consistency.

- Transformation of measuring units.

- Text fields alignment to match defined standards.

2. Clean Data

Clean your datasets to remove inaccuracies and inconsistencies, enhance the reliability of models, and improve the accuracy of delivered results. This helps reduce noise and improve the accuracy of delivered insights.

The top data-cleaning activities are:

- Duplicated records identification and removing

- Identify data errors, typos, or irrelevant data

- Remove irrelevant data that may negatively affect analysis outcomes

3. Identify Missing Records

Review datasets to detect gaps in records and missing data, which is crucial for conducting predictive analytics. This step is useful for reducing biases and increasing the accuracy of forecasts.

The useful activities for identifying missing records include:

- Utilization of data profiling tools to automatically identify missing values

- Exploration of the root causes of having missing data in your datasets

- Development of missing data handling strategy

4. Detect Outliers

Identify records that are significantly different from the average value. The outlier removal helps avoid data analysis distortion. Extremely different values can negatively impact the accuracy of predictive analytics results.

The foremost outlier removal activities are:

- The implication of statistical data analysis methods

- Analysis of the impact of outliers on demand forecasting models

- Development of a strategy to remove, transform, or investigate outliers further

5. Validate Data

Data validation helps ensure that your records remain accurate and reliable. It also helps ensure that no errors occur, leading to incorrect or irrelevant result generation.

The following activities can help validate data for further analysis:

- Implementation of automated data validation tools

- Continuously review data metrics

- Compare datasets with records from verified sources

Supply Chain Forecasting Challenges

Even the simple moving average, the most straightforward forecasting method, can be accurate if a product experiences steady or no changes. However, many unexpected circumstances can negatively affect the accuracy of predictive models.

The top challenges of forecasting in supply chains are:

Data Quality

The more data you have, the more accurate predictions you can make. Hence, large amounts of historical data from various sources are required to build models that forecast changes, considering as many variables as possible. However, businesses often struggle to get the right amount of data because it usually appears incomplete, outdated, or inaccurate. Moreover, they lack data-sharing pipelines to fetch information from external sources automatically.

Example: A large electronics retailer collects only basic information about sold products automatically. Workers must fill in additional information when they sell an item to a customer. The workers make mistakes, leave records empty, or submit basic information because they need to serve a lot of customers quickly. Consequently, the quality of data is poor, comprising incorrect or incomplete records.

Challenge solution: The development of an automated data collecting and pre-population system to facilitate employee data entry. Also, the solution requires implementing a data cleansing tool to ensure data accuracy and consistency.

Complex Supply Chains

The complex supply chain of global retailers include a lot of parties and integrated systems. Hence, they develop custom integration systems to exchange information with suppliers, distributors, customers, retailers, and many isolated solutions used by a company.

It leads to the challenges of identifying data sources and understanding how

Example: A retail company needs to manage a complex supply chain, comprising thousands of suppliers from diverse countries. They use diverse inventory systems, languages, codes, data management approaches, etc. Consequently, it’s challenging to create a single database of inventory data that is collected and updated automatically.

Challenge solution: Create a custom unified system that allows suppliers to easily submit data independently. Data mapping software may be required to transform records received from suppliers in different formats.

Returns

Poor quality of products, an irrelevant marketing campaign, or other issues can cause many return cases. The percentage of returns can hardly be predicted. Also, they cause an extra load on transportation and storage facilities, promoting extra expenses and revenue losses.

Example: An online apparel company experiences a high rate of product returns because customers often return clothes that don’t fit them well or don’t match their expectations. Hence, the company can hardly create a solid item replenishment strategy.

Challenge solution: Analyzing the root causes of returns by interviewing customers. Update a demand forecasting model by implementing customer behavioral patterns.

Unexpected Issues

Unforeseen global events or other issues can change trends rapidly and cannot be forecasted. Event-based demand spikes and drops are impossible to predict by analyzing historical data because they occur unexpectedly and one time only, lasting until manufacturers and suppliers adjust their strategies.

Example: A grocery retailer failed to meet the demand spike for coffee caused by the news that the global droughts will raise the price of coffee beans on the global market in the future.

Challenge solution: Implement a custom system for monitoring and analyzing real-time data. It helps quickly identify changes in product purchasing patterns to respond quickly by manually adjusting inventory and replenishment strategies.

Insufficient Infrastructure

A dedicated infrastructure is required to store and process large amounts of data, such as petabytes or exabytes of raw information. Businesses seeking new solutions for forecasting methods in the supply chain face a widespread issue of lack of budget or expertise to configure infrastructure for analyzing big data.

Example: A small manufacturing company has an insufficient digital infrastructure that heavily relies on manual program configuration and paper spreadsheets. The limitations do not allow the company to collect large amounts of inventory data for further analysis. Moreover, the usage of isolated software solutions requires employees to export/import all the data manually.

Challenge solution: The development of a cloud-based infrastructure and automated data-sharing pipelines for collecting and analyzing all the data in a remote server.

To Recap — The Future Of Forecasting In Supply Chains

The forecasting supply chain management niche develops at a high pace thanks to the rapid adoption of new technologies by different organizations. These days, companies that operate in logistics and supply chain management find spreadsheet-based forecasts insufficient.

The accuracy of predictions is one of the main characteristics of forecasting in the supply chain. AI- and ML-enabled solutions help businesses get more accurate and data-baked forecasts. According to recent research, 80% of businesses already use or plan to adopt machine learning and artificial intelligence to optimize their processes and keep up with their competitors.

FAQ

It is the process of using various techniques to predict different events. Supply and demand planning is one of the foremost objectives of forecasting in supply chains. It helps businesses that operate in the logistics niche optimize their operations and improve efficiency.

There are two types of supply chain forecasting methods: quantitative and qualitative.

The top five methods for quantitative forecasting in supply chain management are:

- Simple moving average

- Adaptive smoothing

- Autoregressive integrated moving average

- Life cycle modeling

- Multiple aggregation prediction algorithm

The four most popular qualitative forecasting methods are:

- Historical analogies

- Panel consensus

- Market research

- The Delphi method

Forecasting in supply chain management helps businesses optimize their operations to increase efficiency and cut expenses.

The core benefits of building predictive models for businesses that operate in the supply chain niche are:

- increased sales

- decreased storage and utilization fees

- fast delivery

- efficient supply chain management

- improved customer experience

Many companies achieve significant results by adopting forecasting solutions. There are three successful case studies:

- Axiom Telecom improved stock optimization by 15%

- More Retail increased sales forecasts by 49%

- Sunsweet Growers shut down 70% of its warehouses

The four most used technologies to predict the demand in supply chains are:

- Manual forecasting

- Spreadsheets

- Third-party software

- Machine learning and artificial intelligence

The best way to start building forecasting models is to find an experienced partner with hands-on expertise in big data analysis.

It’s advisable to take the following steps:

- Define your requirements

- Find a trusted tech partner

- Gather data and prepare it

- Test and implement

Related services and industries

Logistics Software Development

Get solutions designed to streamline operations

Build your ideal custom software today