Supply Chain Visibility Software

Supply chain visibility solutions enable the opportunity to oversee all the operations and movements.

Data collection, processing, and sharing are enabled by technological solutions and real-time logistics tracking software. They help automate processes and create data-sharing pipelines for monitoring all the activities without any delays.

Supply Chain Visibility — Basics

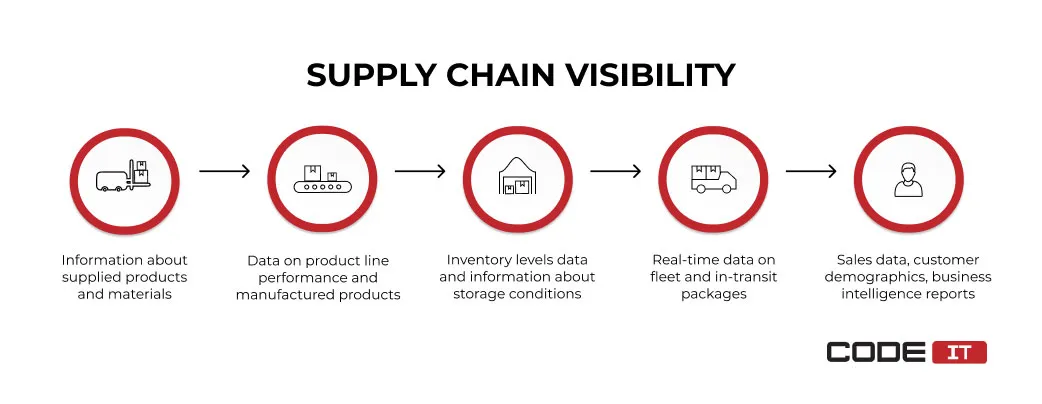

End-to-end supply chain visibility solutions help businesses track all the processes using a centralized unit.

The core processes and activities that need to be visible in an effective supply chain are as follows.

- Product and material sourcing. An integration with the supplier software helps track the status and location of sourced goods.

- Manufacturing. Monitor the production performance and control quality in live time. Get custom reports and alerts about unforeseen issues instantly.

- Inventory levels. Control the in-stock and in-progress inventory. Receive notifications when the level of in-stock products or materials falls below defined points.

- Warehouse conditions. Use a centralized warehouse management system to monitor and adjust conditions like temperature, humidity, and other crucial factors.

- Fleet and transportation. Track the location of vehicles in real-time. Build the best routes and check the estimated delivery time.

- Order fulfillment. Monitor sales, picking and packing performance, and delivered items.

- Payments. Control financial operations, including returns and receipt issuing.

- Customer and supplier relationships. Enable transparent relationships with customers and suppliers. Collect feedback, manage refunds, and handle unexpected disruptions.

Create a supply chain visibility platform

Considering the key factors, let’s compare a fully visible to an opaque and non-optimized supply chain.

| Fully-Visible Supply Chain | Unoptimized Supply Chain | |

|---|---|---|

| Transparency | All the information about inventory data is accessible in a centralized tool. Inventory updates are delivered instantaneously. | Cycle counting and manual data updates lead to data collection and processing gaps. |

| Risk Management | Possible issues and risks can be detected early thanks to real-time data tracking and predictive analytics. | Delayed data collection and processing leads to delayed problem identification that cannot be quickly mitigated. |

| Performance | Automation and real-time data-sharing pipelines help increase performance and reduce errors. | High manual labor intensity leads to decreased performance and a higher chance of human error. |

| Supplier Management | Transparent processes and comprehensive data-sharing capabilities help enable effective collaboration. | A high chance of misunderstandings and irrelevant data sharing caused by limited communication capabilities. |

| Agility | Access to real-time data updates enables rapidly adjusting supply chain management strategies. | Data update lags and insufficient inventory data may lead to outdated or irrelevant supply chain adjustments. |

| Data Analysis | Real-time data summarization and visualization. AI-driven demand forecasting and data analysis. | Datasets scarcity and limited analysis capabilities. Data may be stored in spreadsheets and processed manually. |

The main problems solved by supply chain visibility include the following.

- Inventory data update lag

- Supply chain disruptions

- Poor demand forecasting

- Insufficient quality control

- Low customer satisfaction

- Inadequate supplier management

Supply Chain Visibility Solutions

The end-to-end supply chain visibility solutions comprise hardware and software perfectly aligned with business needs.

Let’s check the hardware and software solutions aligned with supply chain processes.

1. Procurement

The process of acquisition of items and materials from suppliers needs to be predicted and transparent. Hence, a collaboration workflow should be established using the following supply chain visibility software and hardware.

Software

- Supplier relationship management (SRM) software. Interact with suppliers using a centralized tool. Manage operations, place orders, check estimated delivery time, etc.

- Enterprise resource planning (ERP) system integration. Acquire data from suppliers and integrate it into your ERP system automatically.

- Inventory management system (IMS) integration. Add inventory data from scanned UDIs and RFID tags to the main server automatically.

Hardware

- RFID tags & UDIs. Get and issue unique UDIs upon a need. Read data from RFID tags and write new information.

- GPS trackers. Monitor the movement of products in live time. Arrange business processes and allocate the labor force in advance.

- Barcode and RFID scanners. Scan packages arrived at a warehouse. Enable automatic scanning and data transfer.

2. Storage

Pick the most optimal storage space and monitor conditions. Monitor inventory stock levels and warehouse management operations.

Software

- Warehouse management system (WMS). Pick the most optimal storage spaces and monitor environments in warehouses.

- Inventory management software (IMS). Monitor inventory levels in warehouses and check available spaces.

Hardware

- Internet of Things (IoT) sensors. Use smart devices to monitor storage conditions and adjust them remotely.

3. Manufacturing

Monitor production processes, check the quality of manufacturing processes, and control product lines remotely.

Software

- Manufacturing execution systems (MES). Get instant access to information about manufactured products. Monitor the performance of product lines and access information about materials left.

Hardware

- Internet of Things (IoT) devices. Use smart cameras, scales, scanners, and other devices to monitor product lines.

4. Logistics

Monitor your fleet and track the location of packages in live time, promoting efficient global supply chain visibility.

Software

- Transportation management system (TMS). Plan and monitor logistics operations. Conduct freight audits, manage carriers, create routes, schedule loading/unloading, etc.

- Fleet management software. Manage vehicle fleet, monitor the location of vehicles, assess drivers’ performance, and schedule fleet maintenance.

Hardware

- GPS trackers. Get real-time location data of in-progress packages and calculate estimated delivery time.

- Telematics devices. Control vehicle performance, fuel consumption, location, maintenance alerts, etc.

5. Sales & Analytics

Monitor sold products and get custom reports in live time. Communicate with clients and resolve unforeseen issues effectively. Extract insights from customer data.

Software

- Sales software. Collect information about transactions, returns, fraud activities, etc.

- Customer relationship management (CRM) software. Manage all the interactions with customers, collect client feedback, gather demographic data, etc.

- Business intelligence (BI) solution. Analyze collected data using artificial intelligence (AI). Get hidden insights, enable predictive analytics, and generate reports automatically.

Hardware

- Point of sale (POS) systems. Process sales transactions and collect data about sold products.

Hire CodeIT to develop a business-tailored solution

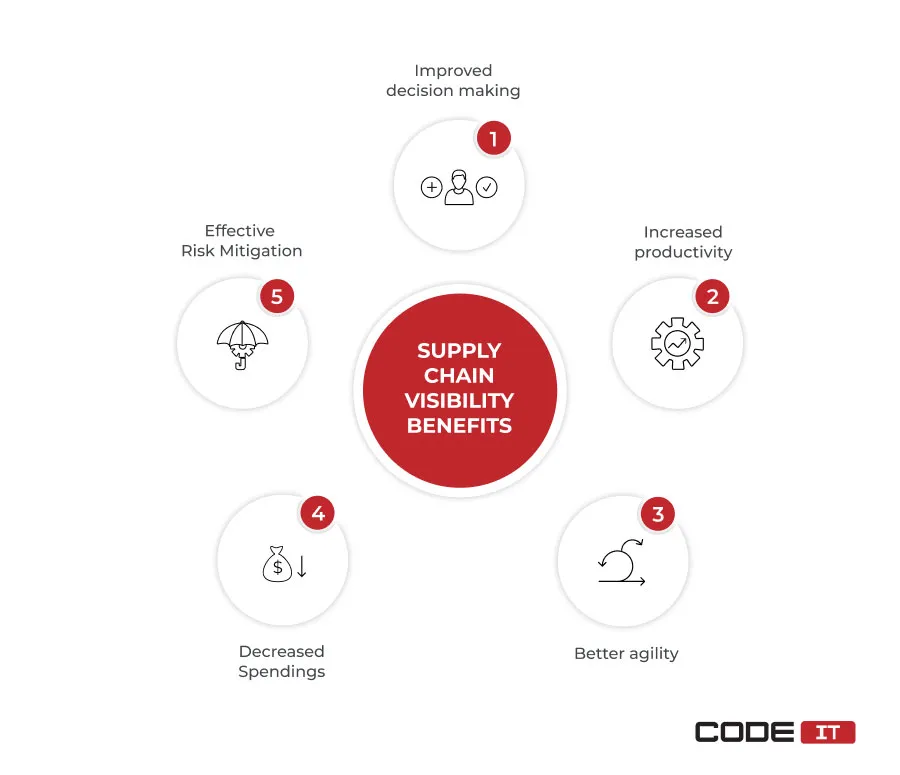

Benefits Of Supply Chain Visibility Software

Supply chain visibility solutions enable the opportunity to meticulously monitor all the processes and rapidly respond to changes. The five main benefits of supply chain visibility are as follows.

1. Improved Decision Making

Having access to the data across the entire supply chain, businesses manage to extract insights and make data-driven decisions. Real-time data access helps rapidly discover trend changes and possible supply disruptions.

Solutions that improve decision-making:

- AI-driven comprehensive supply chain analytics

- Business intelligence

- Centralized data storage

- Third-party software integration

2. Increased Productivity

The integration of end-to-end supply chain visibility solutions helps promote automation and create data-sharing pipelines. Process optimization helps increase performance and reduce errors.

Solutions that help increase productivity:

- Automated barcode scanning

- Warehouse management

- Telematics and fleet management

- Internet of Things (IoT)

3. Better Agility

Real-time inventory visibility helps detect supply chain disruptions at early stages. Moreover, it delivers the opportunity to quickly detect change and adjust business processes and strategies quickly.

Solutions that help improve agility:

- Real-time data access

- Demand forecasting

- Fleet management

- Supplier management

4. Decreased Spendings

Advanced supply chain visibility tools help optimize processes, enable automation, and define points of growth. Comprehensive data analysis helps better understand supply chain processes and find ways to improve them.

Solutions that help cut spending:

- Inventory management

- Warehouse management

- Fleet management

- Data analysis

5. Effective Risk Mitigation

Deep data analysis and early problem identification help better explore possible issues. The implication of AI and other technologies helps develop comprehensive response plans quickly.

Solutions that help mitigate risks:

- Supplier performance monitoring

- Inventory analysis

- Predictive analytics

Implementation Challenges

The development and implementation of supply chain transparency solutions is a complex process. It requires top-tier industry expertise and tech skills to overcome the foremost challenges that may appear.

Data Interoperability

Various systems use and issue data in different formats. Hence, it may be challenging to integrate new hardware or software from diverse vendors into an integrated solution.

Helpful tip: The development of an additional data mapping tool may be required to overcome this challenge.

Tech Stack Diversity

Real-time supply chain visibility solutions may be developed using different technologies. Also, supply chain visibility software may use outdated technologies. It causes software maintenance and upgrade challenges. Also, technology limitations can make it impossible to release new features.

Helpful tip: Pick real-time logistics tracking software wisely or refactor the existing solutions, implementing new technologies.

Security and Compliance

Maintaining inventory data security and compliance may be challenging, especially when using many solutions from different vendors. Running continuous software security monitoring and implementing data security best practices is crucial.

Helpful tip: Enable automatic backup creation and develop disaster recovery plans.

Solution Complexity

Integrated systems that comprise many end-to-end supply chain visibility solutions may be challenging to maintain for a small team of developers. Moreover, the involvement of senior software engineers may be required to implement advanced supply chain visibility tools.

Helpful tip: Thoroughly analyze the implementation solutions and create a detailed team composition plan.

Final Words

Supply chain visibility solutions help businesses comprehensively monitor all the processes and activities using a centralized system. Integrated systems help enable seamless collaboration and data sharing between departments and different companies.

Moreover, all the data collected across a supply chain can be analyzed using AI to discover insights, make data-driven decisions, and forecast demand changes.

Having a fully-visible supply chain enables the opportunity to businesses to monitor:

- Sourced materials

- Product line machines and performance

- Inventory levels and in-stock products

- Warehouse environment

- Fleet and in-progress inventory

- Orders and transactions

- Customer and supplier relationships

FAQ

Global supply chain visibility software allows businesses to monitor all activities and changes using a centralized point. All the data is collected and shared in live time.

The adoption of technological advancements and data-sharing pipelines enables cloud-based supply chain visibility.

The five core benefits of implementing end-to-end supply chain visibility solutions include the following:

- Improved decision-making

- Increased productivity

- Better agility

- Decreased spendings

- Effective risk management

The key characteristics of complete supply chain visibility are as follows.

- Full supply chain transparency

- Effective risk management

- Optimized performance

- Effective supplier management

- Enhanced agility

- Top-tier data analysis

The main software solutions that are applied in a supply chain are:

- Supplier relationship management (SRM) software

- Enterprise resource planning (ERP) system integration

- Warehouse management system (WMS)

- Inventory management software (IMS)

- Manufacturing execution systems (MES)

- Transportation management system (TMS)

- Fleet management software

- Sales software

- Customer relationship management (CRM) software

- Business intelligence (BI) solution

The key hardware components of the best supply chain visibility software solutions are:

- RFID tags & UDIs

- GPS trackers

- Barcode and RFID scanners

- Internet of Things (IoT)

- GPS trackers

- Telematics devices

- Point of sale (POS) systems

The main challenges of implementing supply chain visibility solutions are as follows.

- Data interoperability issues

- Tech stack diversity

- Security and compliance requirements

- Solution complexity issues

Related services and industries

Logistics Software Development

Get solutions designed to streamline operations

Build your ideal

software today