Inventory Management Software Development Guide

Inventory management defines the process of purchasing, storing, and distributing goods. It ensures that a business has the right amount of in-stock goods to satisfy the demand without holding too much inventory.

The three basic steps of inventory stock management are:

- Purchasing. Items are acquired and transferred to a warehouse.

- Storing. Inventory is checked and sorted. Products are transferred to defined places in storage facilities.

- Distribution. Purchased products are pulled for packaging and delivery.

Below, you will find detailed instructions on how to create a custom inventory management system that helps control and automate processes at all stages.

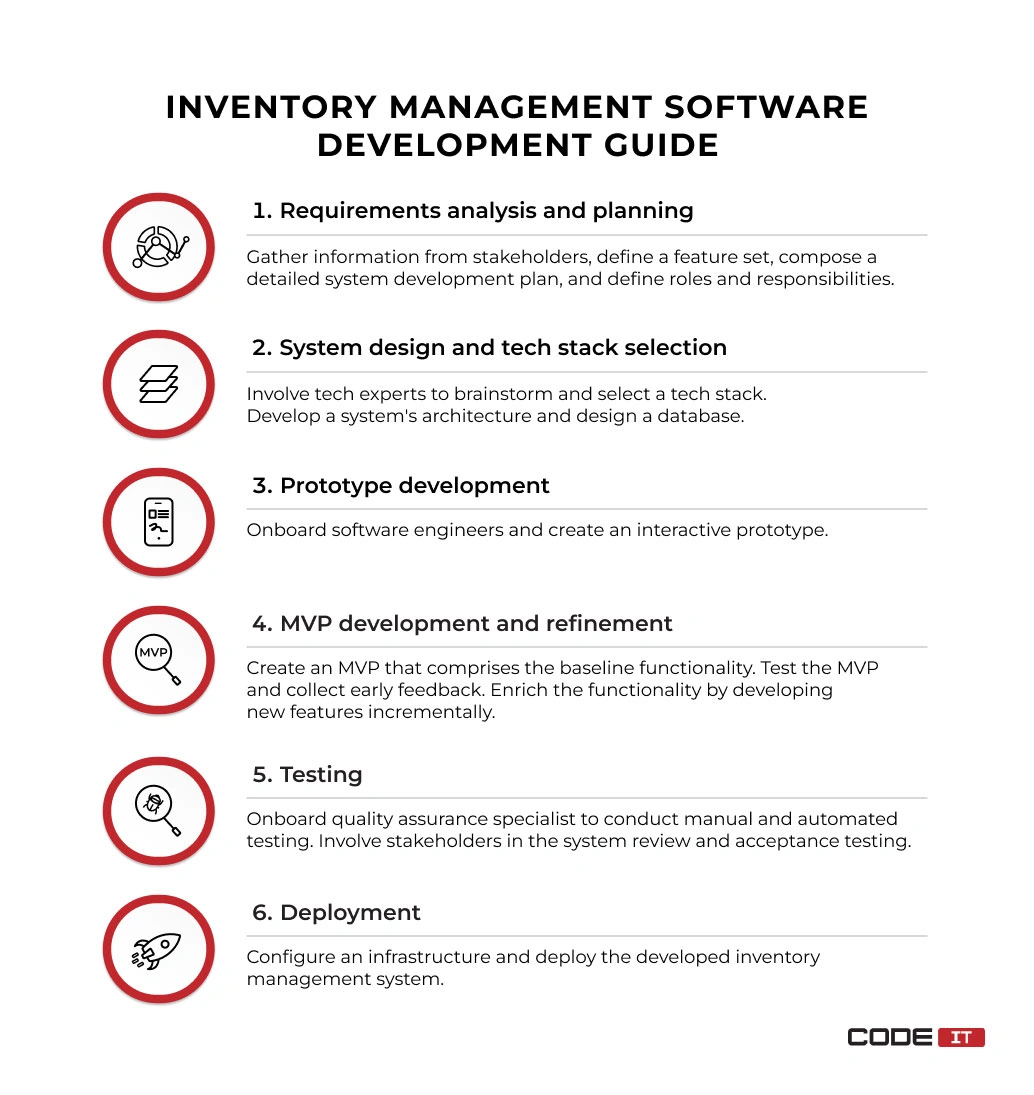

Inventory system development guide

Explore the inventory management development guide below. Also, you will find the input and output artifacts and roles that should be involved in every stage.

1. Requirements Analysis and Planning

Gather information from stakeholders, including functional and business requirements. Also, it’s required to collect technical and API integration requirements if they are available.

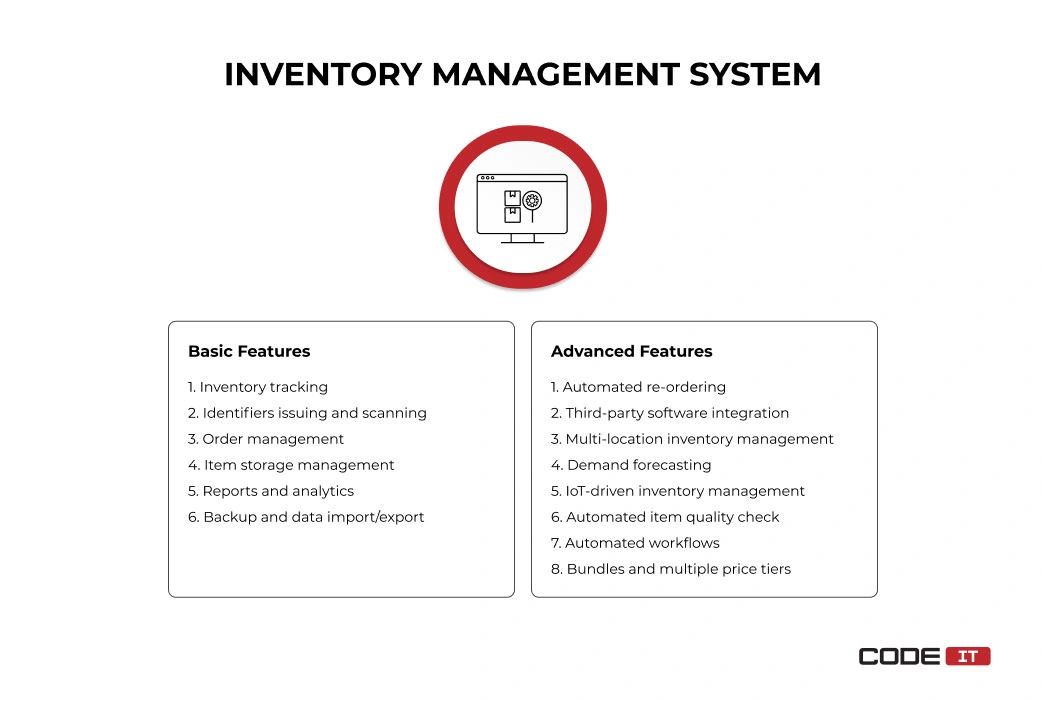

Define a feature set. Analyze business objectives and problems to identify the most important features before you begin the inventory management software development.

Compose a detailed plan for inventory management software development by decomposing primary tasks into user stories. Each should have a clear “definition of done” and key performance indicators (KPIs) assigned.

Define the roles and responsibilities of everyone who has to be involved in the development project. The responsibility assignment (RACI) matrix is a convenient tool that helps effectively map out all roles and responsibilities in a software development project.

| Input Artifacts | Output Artifacts | Roles Involved |

|---|---|---|

| Product vision Stakeholder interviews Business objectives | Software requirements specification Defined roles and responsibilities (RACI matrix) Backlog of tasks | Business analyst Project manager Stakeholders |

2. System Design and Tech Stack Selection

Involve tech experts, including a system architect, a tech lead, and a UI/UX designer.

Brainstorm to select technologies and an logistics software development approach that matches all the requirements.

Develop a warehouse management software architecture. Create wireframes and UX design of a system. Also, create a user interface following corporate design guidelines.

Create a database design, including the data flow and entity relationship schemes. Define the required infrastructure to run an on-premises or cloud-based inventory management system.

| Input Artifacts | Output Artifacts | Roles Involved |

|---|---|---|

| Software requirements specification Feature-set Backlog of tasks Product vision Budget and timeline | Inventory management system design UI/UX design Database schema Data flow charts Entity relationship diagram | System architect UI/UX designers Technical lead Stakeholders |

3. Prototype Development

Onboard software engineers. They have to build inventory management system prototype comprising the baseline functionality. Developing an inventory management system prototype aims to visualize an app, test the concept, and gather feedback.

Create an interactive prototype following the prepared system design and UX/UI requirements. In most cases, a prototype does not comprise the back-end functionality. Front-end developers may implement the core features using alternative tools and technologies.

Test the prototype and gather feedback. Examine its usability and define possible issues in the early stages. Check if the functionality of a solution helps solve defined issues and achieve business goals. Gather the feedback and adjust the backlog accordingly to updated requirements and UX/UI design.

| Input Artifacts | Output Artifacts | Roles Involved |

|---|---|---|

| System design document Software requirements specification UI/UX design | Interactive prototype Feedback Updated requirements and UI/UX design Adjusted backlog | Front-end developers Business analyst Project manager Stakeholders |

4. MVP Development and Refinement

Onboard front-end and back-end software engineers. They need to establish an environment to develop an inventory management system by installing the required tools and setting up a version control system.

Establish collaborative and management environments. Install communication and project management tools to track the progress. Also, create a communication plan to make all the processes clear and transparent.

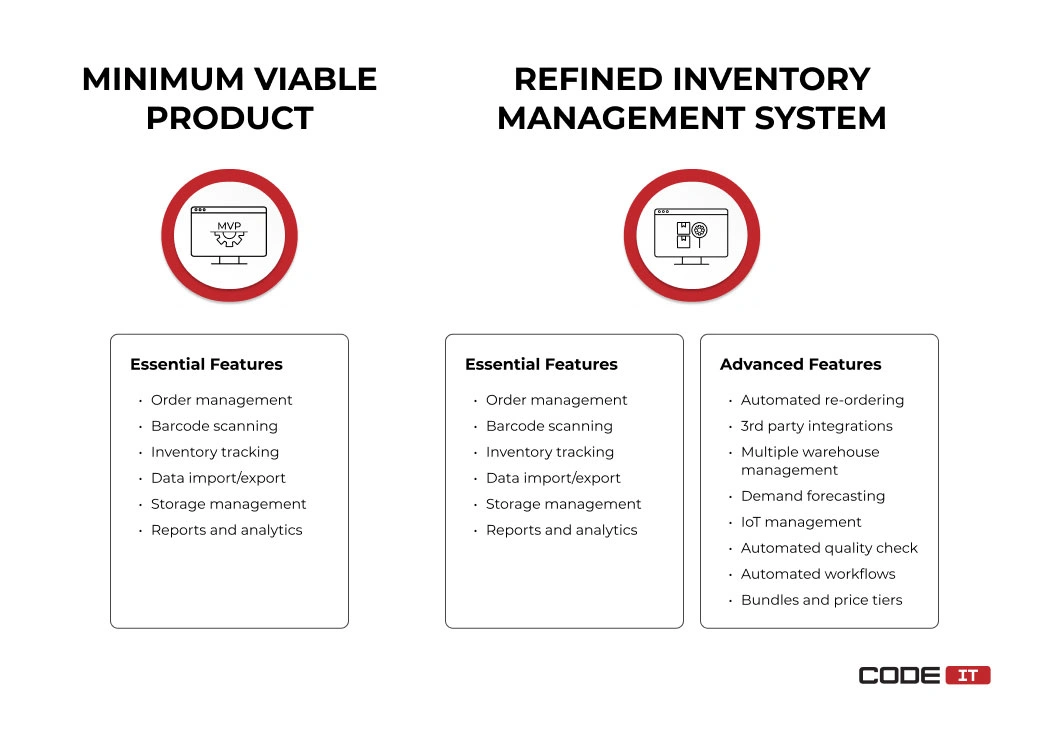

Develop a minimum viable product (MVP) version of your software. It is the initial version of your software that comprises the baseline features. It helps make the inventory management software development process efficient by releasing a product as fast as possible. Also, onboarded tech experts have to create a database, configure an infrastructure, and connect third-party services via APIs.

Release and test the MVP of an inventory management system being used in a real-world environment. The early feedback helps detect unforeseen issues and optimize an inventory management system.

Add more features incrementally to enhance the functionality of the developed system by implementing the most crucial ones first. Connect additional components via APIs to enrich a system’s capabilities.

Create technical documentation that describes how the system is built and works. It will help onboard new developers easily to create new features and maintain the application. Also, technical writers may be involved in creating user guides to educate staff on using a new system.

| Input Artifacts | Output Artifacts | Roles Involved |

|---|---|---|

| System design document Software requirements specification UI/UX design Database schema Entity relationship diagram Backlog of tasks RACI matrix | Minimum viable product Inventory management system features Technical documentation User guides | Front-end developers Back-end developers Full stack developers Project manager Technical writers Stakeholders |

5. Testing

Onboard quality assurance specialists to test the developed inventory system. They need to configure a testing environment and thoroughly examine the system.

QA experts have to conduct automated and manual testing. They can conduct penetration testing to identify possible loopholes and security issues. Besides, QA specialists must compile a detailed report on all the identified bugs and issues. The report needs to be delivered to software engineers so that they can fix all the issues.

Stakeholders need to run acceptance testing. They have to thoroughly examine the developed inventory management system to ensure that it works as expected. Acceptance testing helps ensure that the software meets all the requirements and helps achieve defined business goals.

| Input Artifacts | Output Artifacts | Roles Involved |

|---|---|---|

| Developed inventory management system Technical documentation | Bug reports Test reports Stakeholder feedback | Quality assurance specialists Project manager Stakeholders |

Software Code Audit

6. Deployment

Deployment is the final inventory management software development step. It results in a live inventory management system available for commercial application.

System administrators have to configure an on-premises or cloud-based infrastructure and configure database management procedures.

Back-end developers must establish a production environment and deploy the software. They may also be tasked with migrating inventory data to a new system.

| Input Artifacts | Output Artifacts | Roles Involved |

|---|---|---|

| Developed inventory management system | Established infrastructure Live inventory management system | Back-end developers System administrators Project manager |

Need help developing a tailor-made IMS?

Business First

Code Next

Let’s talk

Why develop inventory management system

Inventory can be managed manually using spreadsheets or by utilizing digital software—inventory management systems.

By developing an inventory management system, businesses manage to automate processes, reduce errors, enable real-time inventory visibility, etc. The five core benefits of stock control software development are as follows.

- Improved inventory accuracy. Using inventory management systems helps achieve a 99% accuracy rate thanks to planning and error elimination.

- Optimized product ordering. Up to 80% of tasks related to inventory replenishment can be optimized or automated.

- Data-baked planning. Historical data analysis and the usage of machine learning models help accurately forecast the demand.

- Reduced inventory costs. Workflow optimization and process automation help cut up to a ¼ of expenses on managing inventory.

- Improved scalability. The functionality of an inventory management system can be scaled up by connecting third-party software and creating automated pipelines.

Let’s compare the two approaches in more detail.

| Manual Inventory Management | Inventory Management System Usage | |

|---|---|---|

| Inventory Tracking | Time-consuming and efficient manual item counting. | Automated inventory counting and real-time data updates. |

| Item Reordering | Continuous in-stock inventory monitoring. Manual stock replenishment requests creation and submission. | Automated item reordering when the in-stock level reaches defined values. |

| Report Generation | Manual data mining and analysis. Time-consuming reports or presentation creation. | Real-time data collection, analysis, and visualization. |

| Accuracy | High chance of errors. | Highly accurate asset tracking and data analysis. |

| Inventory Visibility | Manual item counting should be conducted. | Real-time in-stock inventory visibility. |

| Demand Forecasting | Manual forecast development based on past experience and professional expertise. | ML-driven demand forecasting. Historical data analysis, trend, and repetitive pattern identification. |

| Integrations | Software solutions should be used as distinctive inventory management tools. | Digital solutions from different vendors can be combined into an integrated system. |

Create IMS your business needs to thrive

Business First

Code Next

Let’s talk

CodeIT expertise in inventory system development

The CodeIT team has rich inventory management software development expertise. We’ve created a lot of web- and mobile-based solutions for real-time inventory tracking.

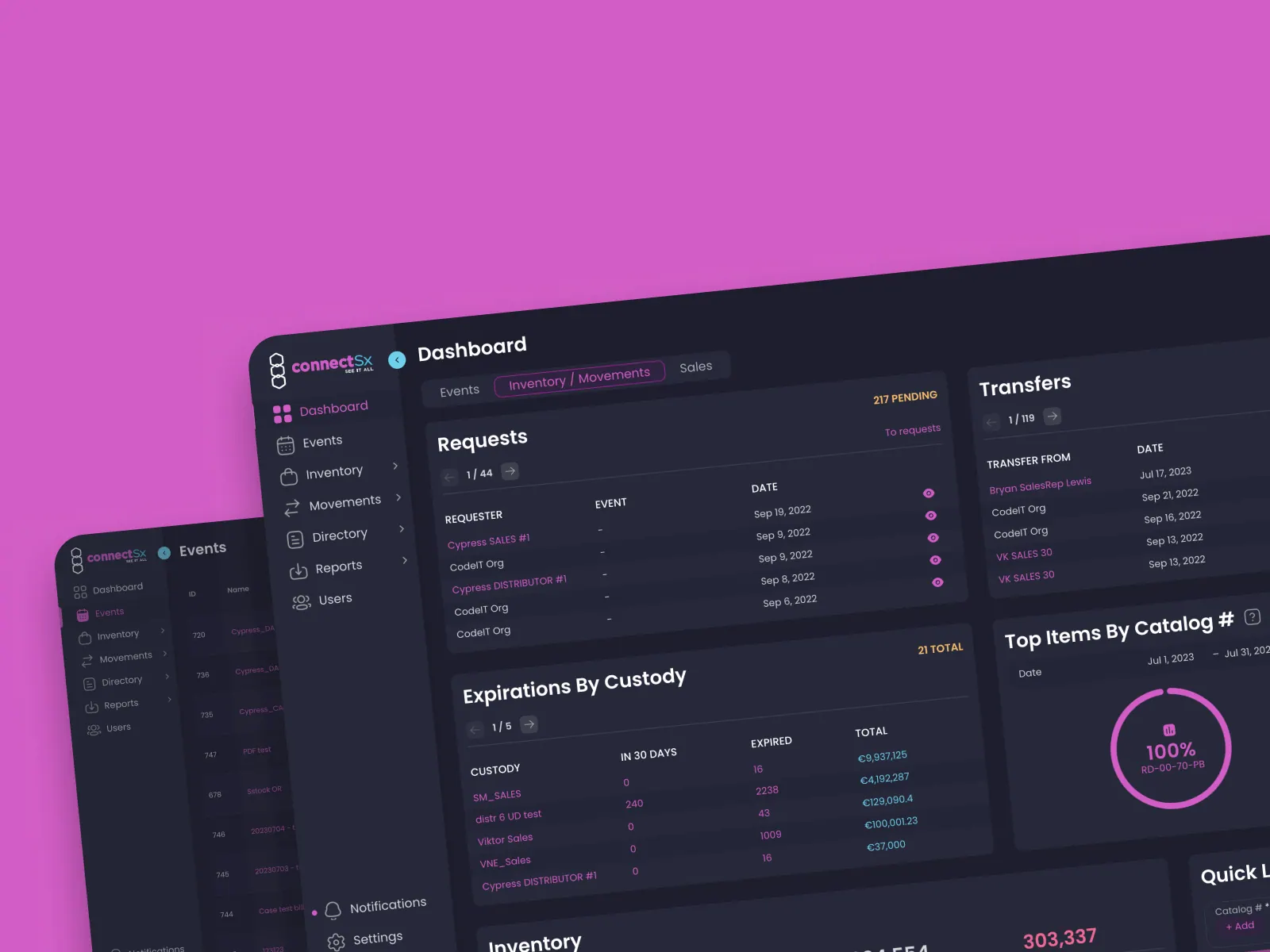

Learn more about one of our recently completed projects — ConnectSx. The system has been developed to enable efficient inventory management in healthcare.

Problem

The client wasn’t unsatisfied with the functionality of the existing inventory management solution being under construction. The CodeIT team was requested to tap into the inventory software development phase and improve the solution.

Solution Implementation

The implementation of the solution was divided into four major phases.

- Team augmentation. A team of CodeIT experts that reached the number of 10 in different phases was dedicated to the project. They were tasked with fixing bugs, optimizing the app, and implementing new features.

- Technical audit. Being unsatisfied with the limitations set by the selected technologies, the client requested CodeIT experts to conduct a tech audit and ideate a better solution.

- Project reboot. The client has reviewed the technical audit and approved the project reboot plan. It aimed to achieve better performance, develop new features, and enable solution scalability opportunities.

- New solution development. We’ve developed the architecture of new software applications and started implementing them using advanced technologies in inventory management.

Result

The inventory management software development project has resulted in three standalone mobile applications developed by the CodeIT team.

- Web application: inventory management system

- iOS app: mobile asset management system

- Cross-platform mobile app: UDI and barcode scanning application

The core features of the implemented solution enable users to do the following.

- Track inventory and submit transfer requests

- Fetch data from third-party systems

- Track product expiration dates

- Track lost medical items

- Collect, analyze, and visualize inventory data

- Scan barcodes

Want to learn more about CodeIT’s input and industry expertise? Check out the case study to discover how real-world applications work.

Inventory software development bottlenecks

The four most widespread bottlenecks that may appear when you develop an inventory management system and their solutions are listed below.

Unclear Requirements

Clearly defined requirements are a crucial part of an inventory management software development process. Following the requirements, software engineers can develop a warehouse management system that aligns with business goals.

Solution: Involve a skilled business analyst at the initial stage. They will help interview stakeholders, identify business challenges, and form a clear vision of a solution that should be developed.

Poor Data Integrity

Software engineers may be required to connect systems created by different vendors when developing an inventory management system. Also, they may be tasked with migrating data from other systems that use different data formats.

Solution: Additional data mapping tools may be required to interpret data in live time. Data cleaning, transformation, and validation steps are the crucial steps that should be conducted when migrating an inventory data set from one system to another.

Tech Expertise Shortage

The lack of tech experts with defined skills may slow down the inventory management software development processes or result in insufficient solutions.

Time-consuming expert scouting, hiring, and onboarding lead to increased inventory system development costs.

Solution: Partner with a skilled vendor with a large technical expert team ready to tap into your project.

Poor System Performance

Unoptimized feature-rich or high-loaded systems may require a lot of resources. Insufficient bandwidth can lead to delays in inventory data updates.

Solution: Involve top-tier tech experts to select the best technologies. Hire software developers to conduct post-deployment system monitoring and optimization.

Adjusting inventory management system for industries

The set of inventory management system features can be adjusted according to the needs of a specific industry. Let’s review how to successfully perform the development process, considering industry-specific requirements and challenges.

1. Manufacturing

Manufacturing companies need to meticulously track raw materials and produced items to avoid overstocking or shop floor idling. They need to handle complex supply chains that comprise suppliers and clients.

Hence, the goal of implementing custom inventory software is to minimize excess inventory while ensuring that production is never halted due to a lack of materials. A custom IMS should focus on demand forecasting, materials allocation, and quality control while supporting lean manufacturing principles to reduce waste.

The key features for tackling inventory management in manufacturing are:

- Inventory tracking

- Order fulfillment and management

- Item storage management

- Reports and analytics

- Automated re-ordering

- Multiple-location management

- Demand forecasting:

2. E-Commerce and Retail

Efficient inventory management is required for retail and e-commerce businesses to deliver products on time. To overcome competitors, they need to have a sufficient number of items in stock to fulfill customers’ demands.

Comprehensive inventory visibility, live-time updates, and integrations with third-party services are essential for running operations smoothly in the industry. Also, businesses need to analyze historical data to forecast future demand and acquire the right number of items to avoid losing sales.

The most important features of an e-commerce IMS are:

- Inventory tracking

- Order management

- Reports and analytics

- Backup and data import/export

- Third-party software integration

- Automated workflows

3. Healthcare

Healthcare providers need to ensure they have the right number of medical supplies to provide medical care. They need to thoroughly monitor storage environments for temperature-sensitive items. Medical organizations need to control the expiry date of medications and implement automated replenishment methods to

The foremost features for healthcare providers are:

- Inventory tracking

- Identifiers issuing and scanning

- Automated re-ordering

- Automated item quality check

- Multiple-location management

- Reports and analytics

In conclusion

The six inventory management software development stages and output artifacts for each are:

- Requirements analysis: system requirements, RACI matrix, feature set, backlog of tasks.

- System design and tech stack selection: inventory management system design, UI/UX design, database schema, data flow charts, entity relationship diagram.

- Prototype development: interactive prototype, feedback, updated requirements and UI/UX design, adjusted backlog.

- MVP development and refinement: minimum viable product, inventory management system features, technical documentation, and user guides.

- Testing: bug reports, test reports, stakeholder feedback.

- Deployment: established infrastructure, live inventory management system.

The main problems that may occur when developing an inventory management system are unclear requirements, poor data integrity, tech expertise shortage, and poor solution performance.

Business needs — first

IMS development — later

Business First

Code Next

Let’s talk

FAQ

An inventory management system is a software application that enables tracking in-stock inventory. It can be supplemented with additional features like barcode scanning, data import, data analysis, etc.

The six inventory management software development stages are as follows.

- Requirements analysis and planning

- System design and tech stack selection

- Prototype development

- MVP development and refinement

- Testing

- Deployment

An inventory management system helps businesses:

- track their inventory in live time

- submit transfer requests

- enable automated product replenishment

- gather and analyze inventory data

The functionality of a system can be further enriched by developing new features and connecting third-party systems.

The main components of an inventory system are:

- inventory tracking system

- data backup and import/export

- identifiers issuing and scanning

- order processing and management system

- storage management

- inventory reporting and analytics

The main bottlenecks and unforeseen problems that may negatively affect the process of developing an inventory management system are:

- unclear requirements

- poor data integrity

- tech expertise shortage

- poor system performance

The main benefits of developing inventory management software are as follows.

- Improved accuracy

- Optimized product order fulfillment

- Data-baked planning

- Reduced inventory costs

- Improved scalability

Related services and industries

Inventory Management Software

Take inventory control, optimize your supply chain, and achieve sustainable growth.

Build your ideal

software today