AI in Inventory Management

Artificial intelligence implies that it is a new trend that helps improve performance and eliminate bothersome activities through automation. AI’s foremost capabilities include analyzing large datasets and answer generation.

AI-driven solutions are usually tailored to tackling specific problems or industry-specific tasks. In the article, you will discover how AI is applied for managing inventory, what challenges it helps overcome, and how the technology is applied in real life.

How Is AI Used In Inventory Management?

Let’s take a deeper dive into traditional inventory management operations and discover how they can be advanced using AI for inventory management.

1. Demand Forecasting

Detailed inventory data analysis helps businesses adjust their replenishment strategies based on seasonal changes, one-time events, and other factors. Traditional demand planning methods usually involve historical sales data reference or the use of simple time series analysis algorithms.

AI-powered demand forecasting

The technology enables businesses to get accurate demand forecasts by analyzing large datasets of structured and unstructured data. The foremost types of data that can be analyzed by using AI inventory management software are:

- Historical data—past sales figures, sales peaks, product returns, revenue, etc.

- Market trends—consumer preferences, social media mentions, competitor pricing, user feedback, etc.

- External data—inflation rates, GDP growth, holidays, seasonal events, demographic data, etc.

- Real-time data—sales data from POS systems, website traffic, social media engagement metrics, etc.

The technology helps extract deep insights by detecting hidden patterns. The analysis of large amounts of data results in highly accurate demand forecasts, minimizing overstock and stockouts.

2. Inventory Replenishment

Traditional stock replenishment strategies usually involve cycle counting and manual order submission. Static re-order point notifications are the most popular method that helps businesses understand when they need to replenish their inventory. Manual re-order processes require workers to spend a lot of time collecting new orders, and there is a high risk of human error.

AI-driven stock replenishment

The access to inventory data forecasts enables an AI-driven system to accurately predict when each stock will reach the minimum threshold, considering repeating events. It can automatically engage new orders, considering the expected rise or fall of demand.

Want to implement AI-driven stock replenishment?

Business First

Code Next

Let’s talk

3. Stock Level Monitoring

The monitoring of actual stock levels can be done manually or automated using spreadsheets and cycle counting. Users can only access defined inventory data using custom dashboards that collect information from different sources.

AI-powered inventory control

The usage of generative AI helps bypass the limitations of tailor-made inventory management systems that display only certain data. AI tools with access to inventory data can understand requests submitted in natural language and translate them into custom SQL code simultaneously. The code can pull out certain data and provide custom insights when the tool executes it.

4. Operations Coordination

Traditionally, operations are coordinated with the help of defined workflows that all employees need to follow strictly. Shift managers are responsible for resolving unforeseen issues and optimizing the existing workflows.

AI-based inventory optimization

The usage of AI-enabled software provides access to real-time insights and predictive analytics. The deep analysis of inventory data hidden patterns helps understand inventory management bottlenecks that need to be addressed and the root causes of problems. Moreover, the technology helps simulate different configurations and workflows to find the best options for optimizing processes.

5. Data Analytics and Reporting

The basic inventory analytics tools deliver real-time metrics and generate reports using the established data-sharing pipelines. Moreover, the analysis of large amounts of data using spreadsheets and basic formulas is limited. Hence, businesses must split their data into isolated spreadsheets to quickly get accurate results.

AI-enabled inventory analytics

AI-driven analytics help gain insights by detecting hidden patterns and processing large amounts of different kinds of data. Furthermore, the generative AI’s capabilities enable users to ask for a tool to pull out certain data and compose custom reports using natural language.

6. Equipment Maintenance

The classic equipment maintenance methods include scheduled inspections. This approach needs businesses to halt their operations and heavily relies on the skills of experts who run visual inspections.

AI-driven equipment maintenance

Predictive analytics in inventory management empowered by AI leverages equipment data to understand when equipment is likely to fail. It helps avoid unexpected downtime and unnecessary inspections that disrupt processes. Moreover, the preventive approach helps detect equipment problems at early stages, avoiding costly equipment failures.

Learn more about CodeIT’s expertise in AI development

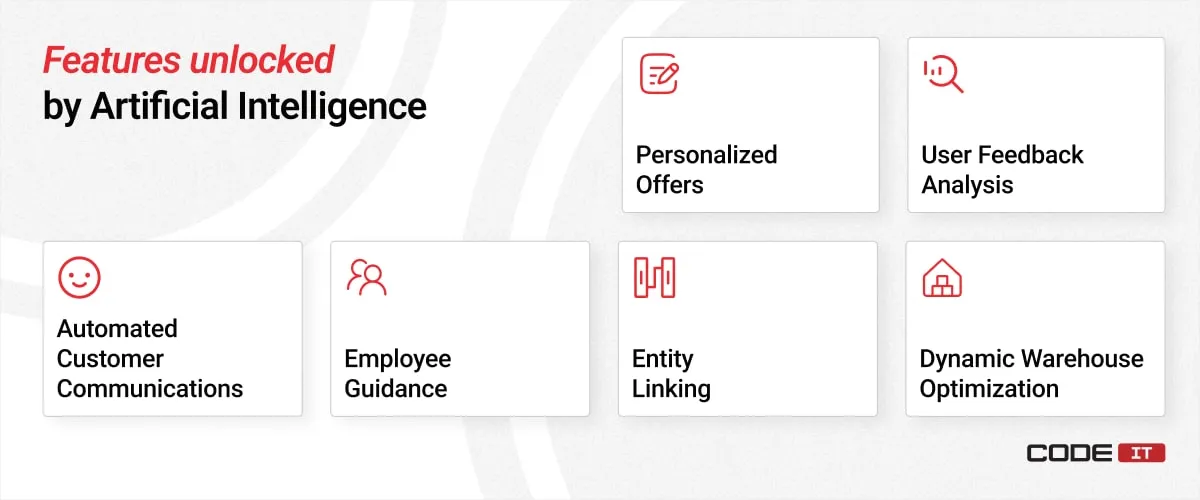

Advanced Features Enabled By AI In Inventory Management

The use of AI in inventory management systems helps unlock forward-looking features that streamline operations and automate bothersome tasks. The foremost advanced features enabled by AI are as follows.

Personalized Offers

AI systems can analyze each user’s purchasing behaviors, preferences, and past transactions. They can suggest items each client is about to purchase. Hence, it can create custom bundles of items for each client, considering the in-stock inventory in real time. Moreover, it enables the ability to offer personalized discounts for bundled products. It helps improve customer satisfaction and increase sales.

User Feedback Analysis

Generative AI algorithms for stock management help pick the best products for replenishment by analyzing user feedback on the Internet. The technology can rapidly access user reviews on other platforms about a defined product and understand the overall level of satisfaction, most widespread issues, etc. Moreover, the generative AI also can summarize user feedback so that it can be further accessed by a real manager.

Automated Customer Communications

An AI chatbot with access to inventory data can automate customer communication. It can understand clients’ requests or questions submitted in natural language and instantly provide data-baked answers. For example, a chatbot can handle the following supplier’s inquiries:

- Order status:“What is the status of my order?”

- Shipping information: “When will my order be shipped?”

- Product availability: “Is product X available in stock?”

- Product specifications: “What are the dimensions of the product X?”

- Invoice inquiries: “Where is my invoice for order?”

Employee Guidance

An AI chatbot trained on corporate guidelines can facilitate workers’ daily operations by providing them with instant instructions. It eliminates the need for workers to browse a knowledge base for new instructions manually. Having access to the real-time inventory data, an AI tool can guide employees. The foremost instructions an AI-driven tool can provide include the following.

- Stock replenishment: “Restock the item X to the reorder point of 50 units.”

- Product placement: “Move product #123 to storage location B.”

- Order fulfillment: “Pick and pack order #123, prioritizing items with urgent delivery dates.”

- Problem-solving: “In case of a damaged product, follow the damage reporting protocol that is available here.”

- New information: “Find the user manual for the #123 forklift here.”

Entity Linking

AI-enhanced inventory tracking is achieved through the technology’s capability to define relationships and dependencies between items. For instance, it can detect products, suppliers, shipment routes, and regulatory standards connections to relevant information, enabling more accurate insights and efficient decision-making.

It helps to get complete information about certain products, like relevant shipping regulations or safety measures that employees need to adhere to when handling a certain item.

Dynamic Warehouse Optimization

The real-time inventory tracking with AI delivers useful insights on optimizing the warehouse layout and item placement for efficient order picking and storage space utilization. Item popularity, seasonal trends, order volume, and other crucial metrics are analyzed in real time to suggest optimal item placement. The dynamic optimization reduces travel time for pickers, cuts labor costs, and shortens order fulfillment times, all contributing to a smoother and more responsive inventory system.

Inventory Management System Features

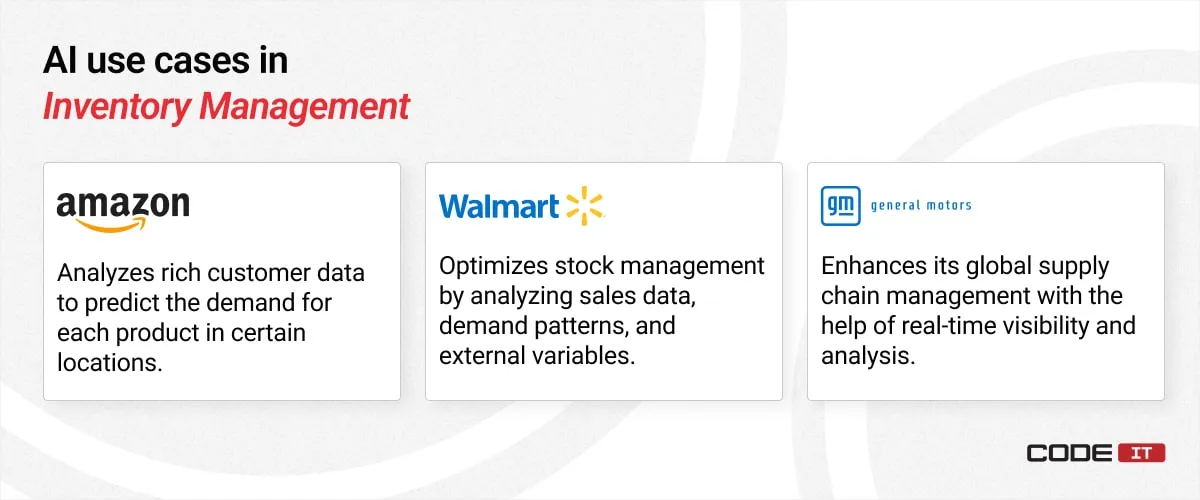

Use Cases Of AI In Inventory Management

Top e-commerce companies utilize AI inventory management software to control their operations and maximize business capabilities comprehensively. Read below the top three real-world companies leveraging machine learning in inventory management.

1. Amazon

It is one of the most tech-advanced companies in the industry. It utilized automated guided vehicles that move racks with items in a warehouse. Moreover, the company uses machine vision for automated package identification.

AI inventory automation platforms help the company to pioneer in item availability and fast delivery thanks to accurate demand prediction. It analyzes extensive datasets of user behavior, preferences, sales history, etc. The system’s insights help the company understand what products are likely to be purchased in each location.

Moreover, the AI-driven insights have helped the company to save up to $1.6 billion in transportation and logistics expenses, which also translated into reduced CO2 emissions.

2. Wallmart

The company has implemented a custom inventory management system that uses Artificial Intelligence to extract insights from all the data they collect. AI algorithms process sales data, demand patterns, and external variables to model future demand and optimize inventory stock across a vast network of stores.

Using AI for inventory management, the company reduced out-of-stock items by 30%. Furthermore, it has implemented an automated item replenishment system. The AI algorithms can also accurately predict the demand during the holiday shopping rush.

3. General Motors

The inventory management AI system used by the company helps optimize its global supply chain management. The tool enables end-to-end inventory visibility by using real-time data analysis.

Using the collected data, the custom software runs simulations to test diverse real-life scenarios. It helps gain comprehensive insights into optimizing workflows and avoiding stockouts.

Build a tailor-made IMS for your business

Benefits Of Inventory Management

Businesses implement AI for supply chain automation to gain a competitive advantage. The technology helps automate workflows, improve efficiency, and run data-baked item replenishment strategies.

Improved Demand Forecasting

The deep analysis of historical data, seasonal trends, market dynamics, real-time purchasing behavior, and other metrics helps get accurate predictions. AI can analyze vast amounts of unstructured data about external factors. The technology can identify hidden patterns and analyze root causes.

Stock Management Optimization

Use data-backed insights delivered by AI-driven software to gain comprehensive visibility of your inventory processes. Detect bottlenecks and run simulations to understand how to optimize workflows, improve efficiency, reduce wastage, and cut operating costs.

Quick Adaptability

AI inventory management software enables the opportunity to quickly respond to changes in market demand, supplier availability, or other unforeseen disruptions. The real-time data analysis instantly provides useful insights on adjusting the replenishment strategy. A business manages to stay resilient and responsive by making dynamic adjustments to its plans and workflows.

Costs Saving

Optimized workflows, enhanced efficiency, and automated activities help cut expenses. AI in stock level forecasting helps minimize overstock, reduce holding costs, and prevent stockouts.

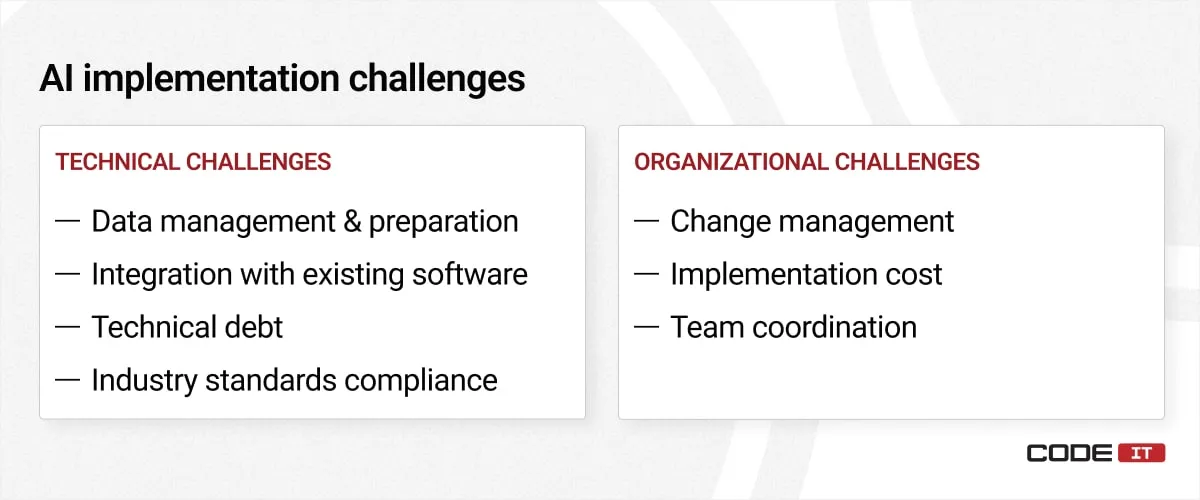

Challenges Of Implementing AI Inventory Management

Implementing AI in inventory management requires top-tier technical expertise and organizational efforts. The foremost challenges experienced by businesses that implement AI in supply chain logistics can be split into the following categories.

1. Technical Challenges

This category of AI implementation challenges describes the difficulties that set AI-driven solutions apart from play-and-play systems and need to be resolved by each business.

1.1. Data management and preparation

The effectiveness of AI systems relies heavily on vast amounts of top-quality and relevant data that are used for training and testing. Since businesses usually fetch data from different sources, it may lead to having a database of inconsistent inventory records that comprise duplicates, invalid data formats, and more.

Consequently, all the collected inventory data needs to be validated and transferred if needed. It may involve a lot of labor-intensive activities.

1.2. Integration with existing software

The real-time analysis requires businesses to develop data-sharing pipelines that help exchange information in unified formats. Isolated systems from different vendors may utilize different data formats. As a consequence, additional data mapping tools for transforming data in real time have been developed.

1.3. Technical debt

The technology is growing at a high pace, and the demand for AI implementation experts is high. This leads to a shortage of top-tier specialists with the required expertise. Moreover, the integration of Artificial Intelligence in supply chain management systems that use outdated technologies may pose significant challenges in developing integrated AI-driven solutions.

1.4. Industry standards compliance

Automated inventory systems used for inventory management must comply with diverse regulatory requirements. Therefore, software engineers need to understand all data privacy and security standards deeply. A detailed description of data handling, reporting, technology usage, and other procedures needs to be prepared by business analysis experts in advance.

2. Organizational Challenges

The organizational challenges refer to internal adjustments, costs, and coordination required to be tackled.

2.1. Change management

Implementing AI inventory management software requires companies to review and significantly change their workflows. It is a time-consuming process that involves a lot of activities.

Moreover, the employees who are used to tried-and-tested workflows will need reskilling. They need to get updated instructions and learning material on how to use new tools. Additionally, a business may be required to run workshops.

2.2. Implementation cost

Implementing AI in logistics and distribution software requires a business to hire BA experts and software engineers with relevant expertise. Furthermore, changing workflows and reskilling employees may pose operation disruptions and additional expenses.

2.3. Team coordination

The implementation of cloud-based AI inventory management solutions requires different departments to collaborate efficiently. Poor coordination can lead to misaligned goals, redundant efforts, or communication breakdowns. Therefore, a dedicated manager is required to manage processes and orchestrate all the activities to ensure smooth solution development and transition to new workflows.

Create a challenge-free software development environment

Business First

Code Next

Let’s talk

Conclusion

The AI in inventory management streamlines workflows and unlocks unique growth opportunities for businesses.

The most popular applications of AI algorithms for stock management are:

- Demand forecasting—analyzes large datasets (historical, market trends, external, real-time data) for accurate inventory prediction using AI.

- AI-driven stock replenishment—predicts when stock will hit minimum thresholds and automates reordering.

- Stock level monitoring—provides real-time insights into stock levels and generates SQL queries.

- Operations coordination—provides real-time insights and predictive analytics to identify bottlenecks.

- AI and data analytics in inventory management—detects hidden patterns and generates custom reports.

- AI-driven equipment maintenance—forecasts equipment failures and helps avoid costly disruptions with early problem detection.

The unique features that AI unlocks in inventory management software include:

- Personalized offers—creates custom product bundles and personalized discounts in real-time.

- User feedback analysis—summarizes online user reviews to gauge satisfaction and identify common issues.

- Customer communications—automates responses to inquiries like order status, shipping details, stock availability, and invoices.

- Employee guidance—offers real-time instructions for tasks like stock replenishment, order fulfillment, and product placement.

- Entity linking—identifies relationships between products, suppliers, shipping routes, and regulations.

- Dynamic warehouse optimization—suggests optimal item placement based on real-time data like item popularity and seasonal trends.

FAQ

AI can be used to manage inventory in various ways, including:

- Demand forecasting—analyzing historical data, market trends, and real-time information to predict future demand.

- Inventory replenishment—automatically triggering reorders based on predicted demand and stock levels.

- Stock level monitoring—tracking inventory levels in real-time and alerting when stock is low or out of stock.

- Operations coordination—optimizing workflows, identifying bottlenecks, and suggesting improvements.

- Data analytics and reporting—generating insights from large datasets to inform decision-making.

- Equipment maintenance—predicting equipment failures and scheduling maintenance to minimize downtime.

AI and IoT can work together to provide real-time visibility into inventory levels and conditions. IoT devices can collect data on factors like temperature, humidity, and product usage, while AI can analyze this data to identify trends and anomalies.

AI can unlock several features in inventory management, including:

- Personalized offers—recommendation of products based on individual customer preferences.

- User feedback analysis—analyzes customer feedback to identify product issues and improvement opportunities.

- Customer communications—automation of customer interactions through chatbots and virtual assistants.

- Employee guidance—real-time instructions to employees on tasks like picking, packing, and shipping.

- Entity linking—identification of relationships between products, suppliers, and other entities.

- Dynamic warehouse optimization—enhancement of warehouse layout and storage locations based on real-time data.

Several companies, including Amazon, Walmart, and General Motors, use AI to manage their inventory. These companies leverage AI to improve demand forecasting, optimize inventory levels, and streamline operations.

The benefits of using AI for inventory management include:

- Improved demand forecasting—more accurate predictions can lead to reduced stockouts and overstock.

- Optimized inventory levels—reduced holding costs and improved customer satisfaction.

- Streamlined operations—automated tasks and reduced manual effort.

- Cost savings—lower operational costs and improved efficiency.

- Enhanced decision-making—data-driven insights to inform strategic decisions.

The foremost challenges of implementing AI for inventory management include:

- Data quality and quantity—AI models require high-quality and sufficient data to be effective.

- Integration with existing systems—the integration of AI solutions with legacy systems can be complex.

- Technical expertise—the implementation and maintenance of AI solutions requires specialized skills.

- Cost—AI implementation can be costly, especially for smaller businesses.

- Change management—overcoming resistance to change and training employees to use new tools.

The future trends in AI for inventory management include:

- Operations automation

- IoT integration

- Sustainable inventory management

- Personalized customer service

Build your ideal

software today