Digital Data Mapping for Automated Line

Industry

Food Processing

Location

Germany

Partnership period

2022 – 2025

Team size

5 FTE

Digital Data Mapping for Automated Line

Our Customer is a family-owned German company founded in 1981, specialising in designing and supplying advanced processing, automation, and packaging solutions for the food industry.

They provide full line systems (from preparation and slicing to packaging and digital products) tailored to many food sectors (cheese, deli, fish, snacks, vegan, etc.).

Challenge

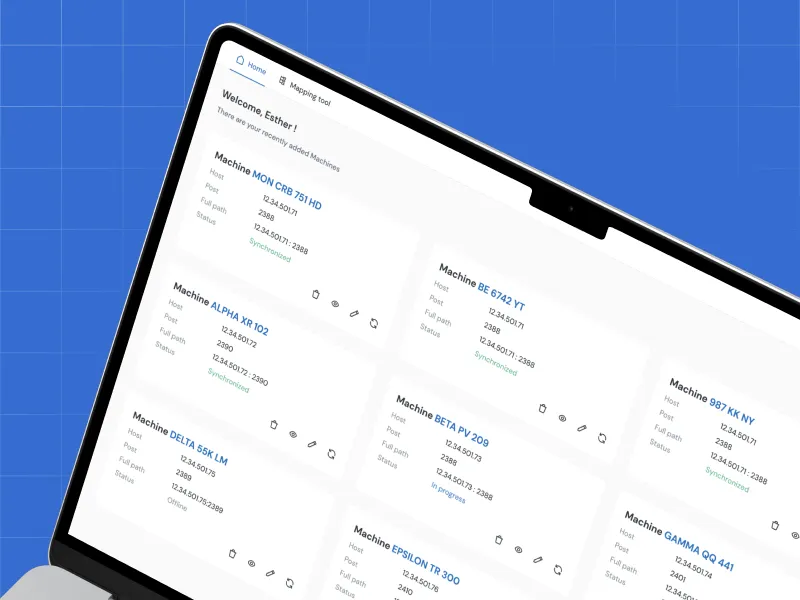

The client aimed to provide their customers with a complete, real-time view of production lines through the FactoryCockpit platform.

Legacy Equipment Blind Spots

Older machines operated on outdated protocols, lacking support for modern data structures and requiring ETL layers to feed into the data lake.

Vendor Fragmentation

Many lines included machines from third-party vendors, producing inconsistent and siloed data streams.

Limited Visibility

Operators struggled to track KPIs such as OEE in real time.

Slow Decision-Making

Incomplete data made it harder to react promptly to performance or maintenance issues.

Costly Modernization Path

Replacing older equipment outright was expensive and not feasible for incremental digitalization.

Solution

Data Mapping for Seamless Machine Connectivity

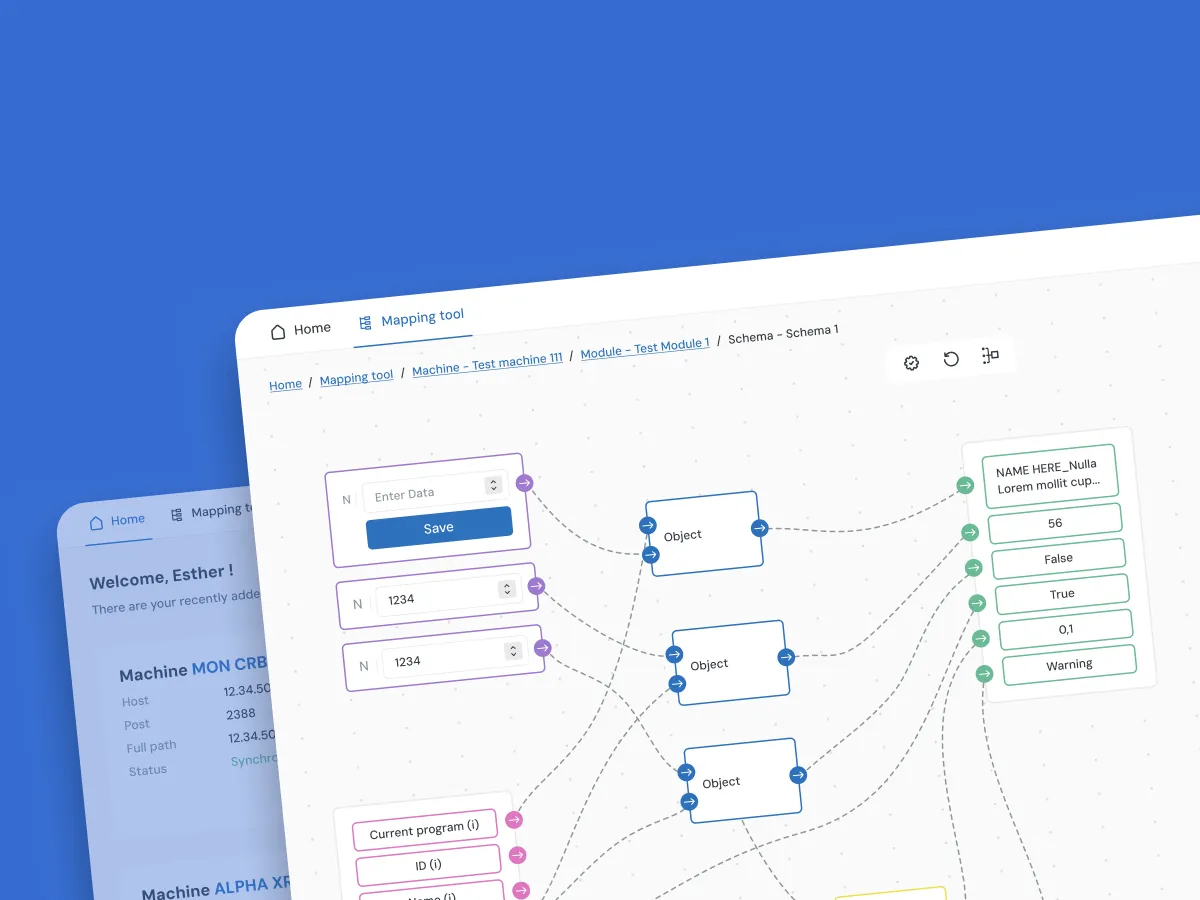

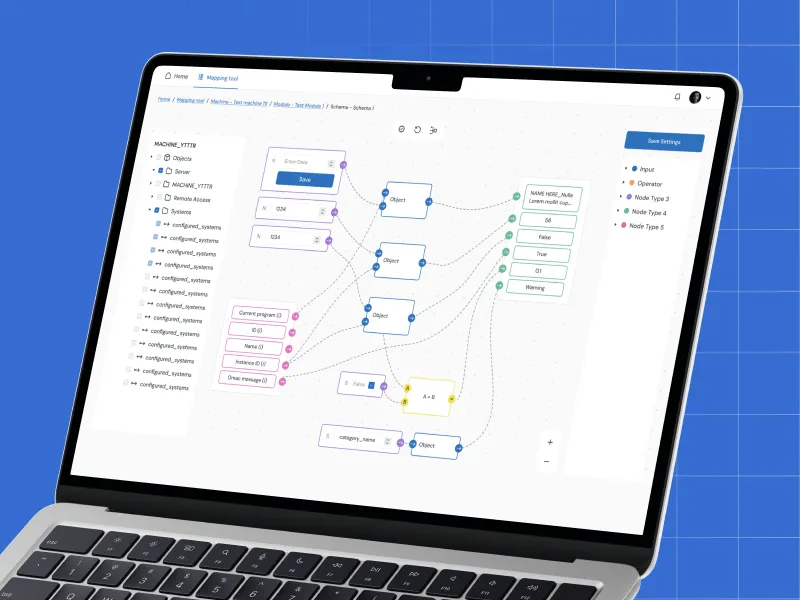

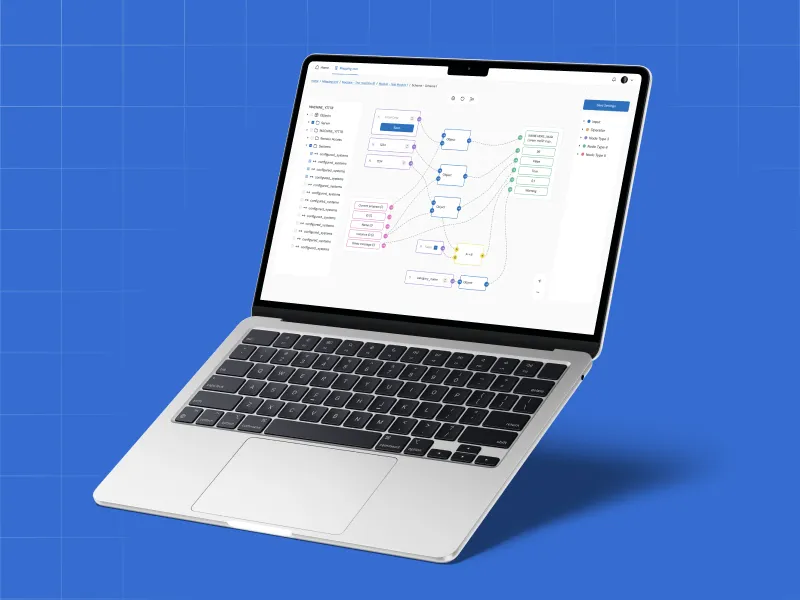

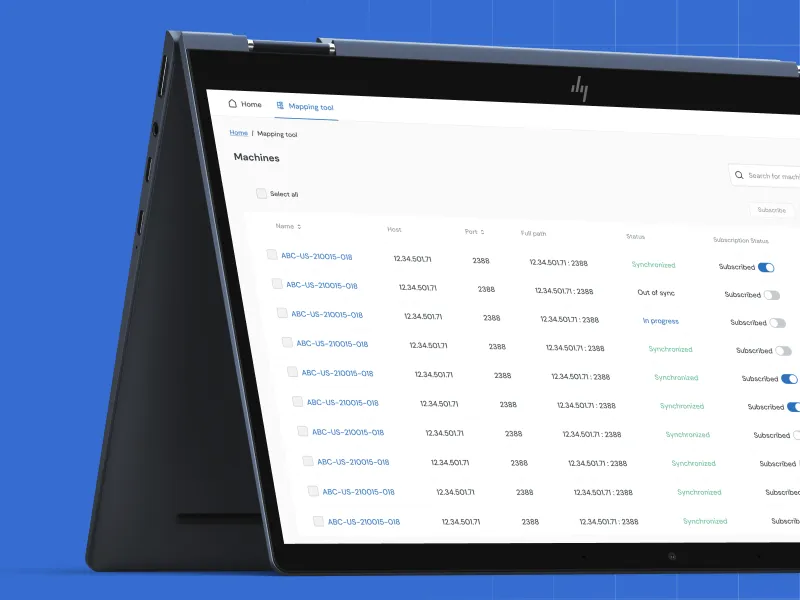

As a solution, CodeIT introduced a digital data mapping tool might be embedded into FactoryCockpit or used as a separate module just to connect 3d party vendor machines.

- Live Data Transformation. The tool converts data from any connected machine into the format accepted by the dashboard or next machine in the line.

- Drag-and-Drop Interface. Production teams can easily design custom data transformation schemes without programming or specific skills required.

- Pre-Configured Building Blocks. Constants, modifiers, and operators speed up configuration.

- Data Validation & Reliability. Automated checks ensure accurate, relevant data flows and reduce errors.

Result

Real-Time Efficiency Without Equipment Replacement

Delivering measurable efficiency gains without costly equipment replacement

- Unified Visibility. Full production line monitoring in a single dashboard, independent of machine vendor.

- Real-Time Insights. Live performance data displayed instantly, enabling quicker operator response.

- Reduced Downtime & Manual Effort. Early detection of deviations improved reliability and efficiency.

- Incremental Digitalization. Clients avoided immediate capital investments in new machines while still gaining digital benefits.

- Optimized Decision-Making. Streamlined access to KPIs like OEE improved production and maintenance planning.

Achievements

Advancing FactoryCockpit and strengthening CodeIT’s expertise in real-time industrial digitalization

- Vendor-Agnostic Leadership. Strengthened FactoryCockpit’s position as a universal line monitoring solution.

- Incremental Digitalization. Enabled customers to digitize lines without immediate machine replacement, simplifying decision-making.

- Future-Proof Platform. Delivered a scalable solution that increased customer adoption and satisfaction.

- Data Standardization Expertise. Built strong know-how in mapping heterogeneous industrial equipment.

- Low-Code Empowerment. Developed a visual interface enabling engineers to configure data flows without coding.

- Mission-Critical Integration. Proved CodeIT’s ability to deliver real-time manufacturing integrations at scale.

Team

- Project Manager

- Data Engineer

- Software Developer

- UI/UX Designer

- QA Engineer